Chopin Chain Making Machine

Jewelry laser spot welding machine, also known as gold and silver jewelry laser spot welding machine or small laser spot welding machine, is an instrument and equipment used for welding gold and silver jewelry, belonging to the category of spot welding machines. This device uses high-energy laser pulses to locally heat small areas of materials, forming a molten pool through thermal conduction to achieve welding. It is widely used in industries such as aviation, aerospace, sports goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles, etc. for hole filling, spot welding seam patterns, embedded parts, and claw foot welding. The main applicable materials include platinum, K gold, silver, titanium gold, stainless steel, copper, aluminum and their alloys.

All-in-one jewelry laser welding machine

Jewelry laser spot welding machine, also known as gold and silver jewelry laser spot welding machine or small laser spot welding machine, is an instrument and equipment used for welding gold and silver jewelry, belonging to the category of spot welding machines. This device uses high-energy laser pulses to locally heat small areas of materials, forming a molten pool through thermal conduction to achieve welding. It is widely used in industries such as aviation, aerospace, sports goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles, etc. for hole filling, spot welding seam patterns, embedded parts, and claw foot welding. The main applicable materials include platinum, K gold, silver, titanium gold, stainless steel, copper, aluminum and their alloys.

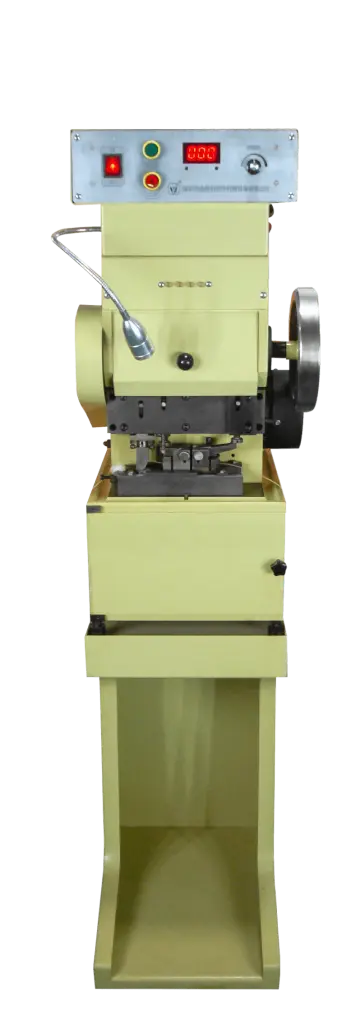

Lip Chain Making Machine

IMG-C-LB500

Lip chain making machine is a machine that performs secondary processing on chains. Generally, it processes cross chains to form new styles of chains. Its working principle is to hammer the two sides of the cross chain, hammering the metal wire into pieces. Different styles of chains can be made by changing the mold style and hammering force. This machine is commonly used in jewelry making tools and can be used to process chains made of different materials such as gold, silver, and copper.

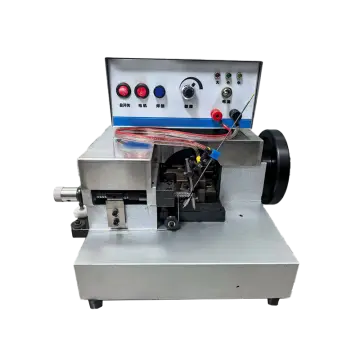

Jewelry Tools Buckle Machines Product...

Chain fastening machine is a semi-automatic, simple and inexpensive machine for making chains. It is used to make small-sized cross chains and can produce chains made of metal materials such as gold and silver. It is suitable for jewelry sellers with small shipments. The machine comes with a tungsten needle for welding, and the overall power of the machine is relatively low. One tungsten needle can be used for more than three years, greatly reducing the cost of later use and maintenance.

100W Mini jewelry laser welding machine

Jewelry laser welding machine is mainly used for spot welding, seam welding, and inlay welding of precision metal parts such as gold and silver jewelry, jewelry, and watches. This device uses high-energy laser pulses to locally heat small areas of materials, forming a molten pool through thermal conduction to achieve welding. It is widely used in industries such as aviation, aerospace, sports goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles, etc. for hole filling, spot welding seam patterns, embedded parts, and claw foot welding. Support precision welding of platinum, K-gold, silver, titanium gold, stainless steel, copper, aluminum and their alloy materials, especially suitable for repairing holes, spot welding sand holes and claw foot parts of gold and silver jewelry.

Rope chain making machine

Shenzhen imagin Technology Co., Ltd. is located in the beautiful coastal city of Shenzhen, China. It is a professional manufacturer of equipment related to jewelry production, such as chain weaving machines, welding machines, point drilling machines, etc. With a commitment to quality and innovation, the company has become a trusted advanced machinery supplier in the jewelry industry.

The rope chain making machine produced by the company uses advanced technology, and the fastest work efficiency can reach 300 revolutions per minute. It can weave necklaces of various sizes and materials with a wire diameter of 0.3mm to 0.8mm. Its unique shape and exquisite design make it a daily accessory for many people. This machine is also an essential equipment in the jewelry industry.

High speed flower batch machine

The flower batching machine (also known as the chain link cutting machine, chain link cutting machine) is a special equipment used for precision cutting, engraving or surface treatment of metal chains (necklaces, bracelets, etc.) in jewelry processing. The following is a detailed description of its core features and working principles:

450 high speed single double cross ch...

High speed chain weaving machine, with the fastest working efficiency reaching 450rpm, can weave necklaces of various sizes and materials with wire diameters ranging from 0.13mm to 0.45mm. The weaving styles include cross chain, curb chain, double cross chain, double curb chain, etc. When weaving, the corresponding mold can be selected according to the corresponding style and wire diameter, and the mold can also be customized according to customer needs.

Automatic high speed rolo chain makin...

The rolo making machine is a specialized mechanical equipment designed and manufactured in the jewelry and other industries. Its fastest working efficiency can reach 150 revolutions per minute, and it can process rolo chains of different materials with a diameter of 1.2-5.5mm. It is particularly suitable for stretching and stamping gold and silver, iron sheets, copper sheets, aluminum sheets, and stainless steel sheets.

Large chain weaving machine

Large chain weaving machine, Its function is the production and processing of chains. As a mechanical system, it mainly consists of power system, drive system, transmission system, execution system, and frame. The execution system mainly consists of three main mechanisms: mechanical mechanism, feeding mechanism, and pressing and cutting mechanism. Through the coordination of the entire system, the copper wire raw materials are sequentially subjected to spiral processing, clamping, cutting, flattening, twisting, weaving and other actions. By automating production, we can reduce labor, compress costs, and improve production efficiency.

The chain weaving machine can weave necklaces of various sizes and materials with wire diameters ranging from 0.5mm to 2.5mm. The weaving styles include cross chain, curb chain, double cross chain, double curb chain, etc. When weaving, the corresponding mold can be selected according to the corresponding style and wire diameter, and the mold can also be customized according to customer needs.

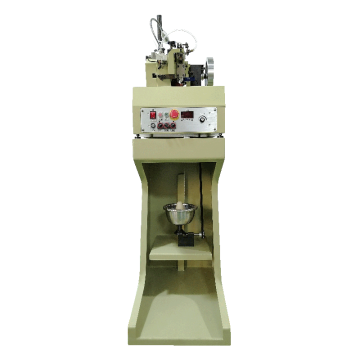

Automatic high speed chopin chain wea...

Product Name: Chopin Chain Making Machine

Machine model:IMG-C-CC500

Bismark chain coupling machine

The bismark chain coupling machine can combine cross chains and curb chain with different wire diameters of 0.2-1.5mm into various styles of necklaces, such as two curb chains, cross chains, four curb chains, cross chains, six curb chains, cross chains, etc.

Computer full automatic lifting hamme...

Hammer chain machine is applied in the field of jewelry processing technology, specifically an electric hammer chain machine. The maximum stamping force can reach 15 tons, and the stamping speed can reach 1000rpm.

Automatic Hammer Chain Machine, capable of hammering cross chains, curb chains, Franco chains, Golden Dragon chains, Great Wall chains, Round Snake chains, Square Snake chains, Flat Snake chains. The main materials include gold, platinum, K-gold, silver, stainless steel, copper, etc.

Automatic high speed rope chain makin...

The rope chain making machine produced by the company uses advanced technology, and the fastest work efficiency can reach 300 revolutions per minute. It can weave necklaces of various sizes and materials with a wire diameter of 0.3mm to 0.8mm. Its unique shape and exquisite design make it a daily accessory for many people. This machine is also an essential equipment in the jewelry industry.

Lily

Lily Jason wong

Jason wong