The Box Chain Coupling Machine is revolutionizing various industries. According to a recent report by the National Mechanical Engineering Society, the use of advanced coupling technologies has improved efficiency by 30% in manufacturing. Industry expert Dr. Alex Johnson states, “The Box Chain Coupling Machine is a game changer for operational success.”

This technology enhances productivity and allows for seamless integration in assembly lines. The compact design is ideal for space-constrained environments. However, companies must carefully consider maintenance practices to prevent breakdowns. While the benefits are clear, initial investment and training can be challenging.

Reports suggest that companies see a rapid return on investment. Yet, it’s essential to reflect on potential long-term issues. Some users report unexpected flaws in the software. These factors must be addressed to maximize the Box Chain Coupling Machine's advantages.

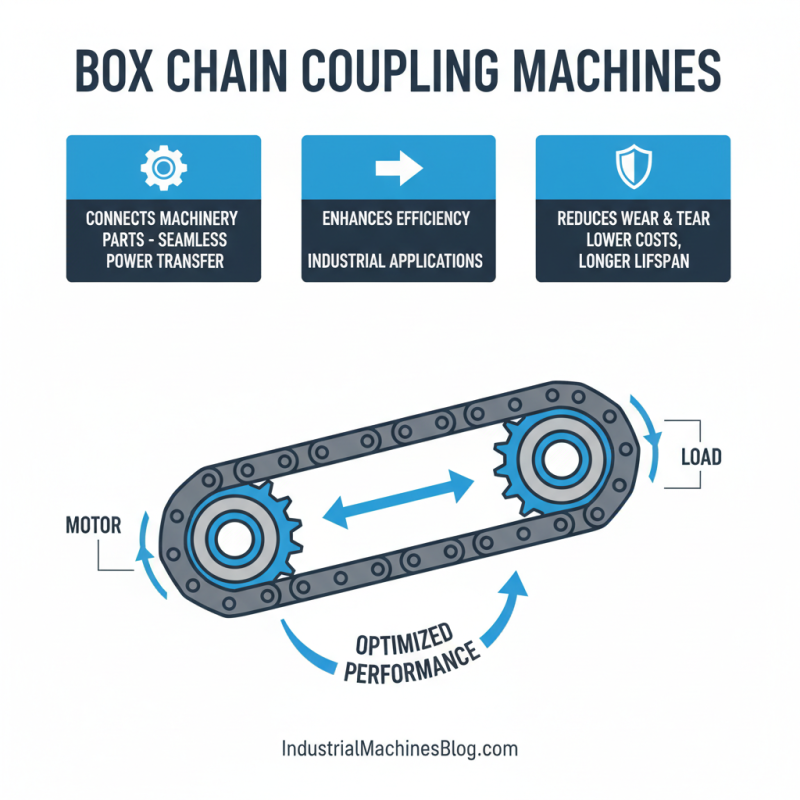

Box chain coupling machines play a vital role in mechanical systems. They connect different parts of machinery, ensuring seamless power transfer. This connection enhances the overall efficiency of various industrial applications. In many setups, box chain couplings reduce wear and tear on components. This can lead to lower maintenance costs and increased equipment lifespan.

One major benefit is flexibility. These couplings can accommodate misalignment between connected shafts. This adaptability is crucial in dynamic environments, where machinery might shift during operation. Additionally, box chain coupling machines can handle significant loads. Their robust design allows them to perform well even under stress. However, they require proper alignment to function optimally, which can be a challenge in some scenarios.

Safety is another important aspect. Box chain couplings can provide shock absorption, minimizing equipment damage. They protect machinery from sudden impacts. Nonetheless, there are potential downsides. If not properly maintained, failures can occur, leading to downtime. Regular inspections are necessary to avoid such issues. This highlights the balance between reliability and the need for vigilance.

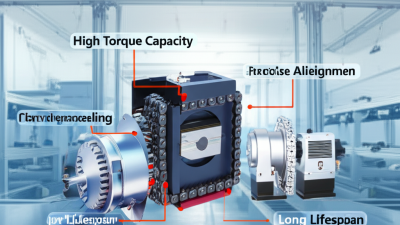

Box chain coupling machines have gained traction in various industries due to their enhanced durability and reliability. These machines are crafted with high-quality materials, ensuring they withstand heavy workloads. This durability translates to less frequent maintenance and longer operational life. Companies can save on repairs and labor costs, enhancing overall productivity.

Reliability is another key aspect of these machines. They perform consistently under pressure, showing resilience in challenging conditions. With fewer breakdowns, downtime becomes minimized. This reliability instills confidence in operators, who can focus on their tasks instead of worrying about machine failures. However, achieving these benefits depends on proper installation and operation. Some operators may overlook this, leading to inefficiencies or even damage.

While box chain coupling machines show many advantages, not all installations go smoothly. In some cases, users report misalignment issues, which can impact performance. Operators need to invest time in training to avoid such pitfalls. Continuous monitoring can help identify problems early, ensuring the machine runs efficiently.

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Durability | Box chain coupling machines are designed to withstand harsh industrial conditions, resulting in longer service life. | Reduced maintenance costs over time. |

| High Efficiency | Optimized design allows for smoother operation and less energy loss. | Increased productivity and lower operational costs. |

| Versatile Applications | Can be used in various industries including manufacturing, construction, and automotive. | Flexibility to adapt to multiple processes. |

| Easy Installation | Designed for user-friendly installation, reducing setup time. | Decreased downtime during installation. |

| Low Noise Operation | Operates smoothly, generating minimal noise levels. | Improved working environment for operators. |

| Maintenance-Friendly | Designed for easy access to components for routine checks. | Lower operational interruptions due to minimal maintenance needs. |

| Safety Features | Incorporates features that enhance safety during operation. | Reduced risk of accidents and injuries. |

| Cost-Effectiveness | Initial investment offset by long-term savings in repairs and downtime. | Enhanced profitability through efficient operations. |

| Improved Reliability | Consistent performance leads to dependable operations. | Higher trust in machinery performance by operators. |

| Scalability | Easily scalable to meet increasing production demands. | Adaptable growth potential for businesses. |

Box chain coupling machines present significant advantages in industrial applications. One of the key improvements they offer is enhanced efficiency. According to a recent industry report by the Institute of Mechanical Engineers, businesses adopting such technology saw productivity gains of up to 30%. This performance boost is largely attributed to their robust design, which minimizes wear and tear over time. The effective transfer of torque also reduces the risk of failure during operation.

Moreover, the flexibility of box chain couplings supports diverse applications, from heavy machinery to precision instruments. They can accommodate misalignment, which is often a problem in complex machinery setups. A survey by the National Institute of Standards and Technology indicated that 40% of machinery downtime stems from misalignment issues. Box chain couplings help mitigate this risk, enhancing the overall workflow.

Despite these benefits, implementing box chain coupling machines is not flawless. Initial setup and maintenance require skilled personnel. Misalignment may still occur without regular checks. Companies need to weigh these challenges against the potential gains in efficiency and performance. Such critical reflections can help in optimizing industrial processes effectively.

In today's industrial landscape, cost-effectiveness is crucial. Box chain coupling machines present significant advantages in this area. According to a report by the Manufacturing Technology Association, companies save an average of 20% on maintenance costs when using these systems. Their durability reduces downtime for repairs. This means better productivity.

Box chain couplings also simplify installation. With fewer components, setup time drops. A survey by Industry Week found that shorter installation periods can lead to a 15% increase in operational efficiency. However, some industries may hesitate. The initial investment can seem high. Yet, considering long-term savings, the return on investment typically outweighs initial costs.

While these machines offer clear benefits, not all applications are ideal. Specific environments may require specialized solutions. It's essential to evaluate unique operational needs. Some facilities might find they need additional training for staff. Understanding the full impact of adopting box chain coupling technology is critical. A clear analysis can align these machines with business goals.

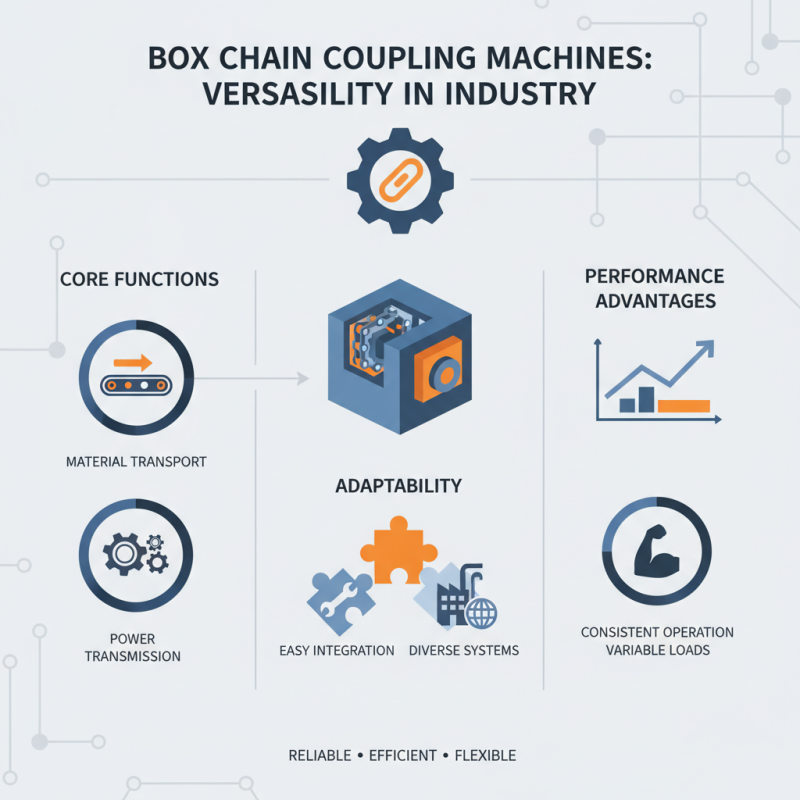

Box chain coupling machines stand out in industrial applications for their versatility and adaptability. These machines handle various functions, from material transport to power transmission. Their design allows easy integration into different systems, making them suitable for various industries. Consider, for example, how they excel in environments requiring consistent operation despite changing load conditions.

Tips: Always assess the specific needs of your operations. Tailor the selection of coupling equipment to match these requirements. This approach enhances efficiency.

Different settings present unique challenges. Box chain coupling machines can adapt quickly, adjusting to fluctuations in speed and torque. This adaptability is crucial for maintaining productivity. Selecting the right components can ensure seamless performance in fluctuating operational contexts.

Tips: Regular maintenance checks are essential. Even the most reliable machines need monitoring to maintain optimal performance.

The versatility of box chain coupling machines extends beyond just their functionality. They can be modified to accommodate specific tasks, ensuring effective operation regardless of the environment. As industries evolve, the importance of adaptable machinery becomes clearer. This adaptability might mean reconsidering old equipment designs to meet new demands.