The jewelry making industry is experiencing a significant transformation with the advent of Automatic Jewelry Tools, which offer artisans unprecedented precision and efficiency. According to a report by Research and Markets, the global jewelry market is projected to reach $480 billion by 2025, driven in part by technological innovations that enhance production capabilities. Automatic Jewelry Tools are at the forefront of this revolution, allowing craftspeople to streamline their processes and reduce labor costs while maintaining high quality. Furthermore, a survey conducted by the Jewelers of America indicates that 68% of jewelers have adopted some form of automation in their production, highlighting the growing reliance on these advanced tools. As artisans increasingly embrace automation, the demand for skilled craftsmanship remains critical, making the integration of Automatic Jewelry Tools a key factor in evolving the traditional art of jewelry making into a modern, competitive industry.

The jewelry industry has long been associated with artisanal craftsmanship and meticulous design, yet the advent of automation is beginning to reshape its landscape. Automation, particularly through the use of robotic arms in workshops, allows artisans to enhance their precision and efficiency. Reports indicate that as much as 25% of jewelry manufacturing processes could be automated by 2025, facilitating a shift from labor-intensive traditional techniques to more streamlined production methods. This transition not only preserves the intricate details of handmade jewelry but also integrates innovations that attract a new generation of consumers.

Moreover, the integration of artificial intelligence into jewelry retail is revolutionizing customer interactions. According to industry studies, AI-driven systems can improve customer engagement by up to 40%, providing tailored product recommendations and streamlining the buying process. Additionally, technology is playing a critical role in sustaining ancient crafts by bridging the gap between tradition and modernity, helping artisans gain access to global markets through e-commerce platforms. As the industry continues to embrace these advancements, it remains crucial to balance automation with the rich heritage of craftsmanship that defines jewelry making.

| Tool Type | Functionality | Impact on Crafting | Adoption Rate (%) |

|---|---|---|---|

| Laser Cutter | Precise cutting of intricate designs | Enhances design complexity and precision | 40% |

| 3D Printer | Rapid prototyping of jewelry models | Speeds up the design process | 35% |

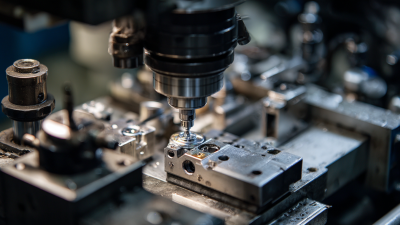

| CNC Milling Machine | Automated machining for shaping metal | Increases efficiency and reduces wastage | 30% |

| Automated Polisher | Uniform polishing of jewelry pieces | Enhances final finish with consistency | 50% |

| Digital Design Software | Tools for designing and visualizing pieces | Facilitates creativity and virtual experimentation | 60% |

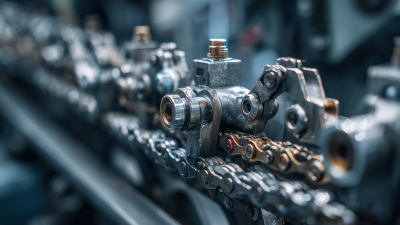

Automatic tools are transforming the jewelry-making landscape for artisans, bringing efficiency and precision to the craft. One significant advantage of these tools is the ability to ensure consistent results with every piece created. Unlike manual methods, which can vary from one artisan to another, automatic tools deliver a level of uniformity that enhances the quality of the finished product. This consistency allows artisans to focus on creative design elements while the tools handle repetitive tasks such as polishing, setting, and cutting.

Tips for integrating automatic tools into your jewelry-making process include starting with simple, user-friendly devices. This allows you to familiarize yourself with the technology without feeling overwhelmed. Gradually expand your toolkit as you become more comfortable. Additionally, consider scheduling regular maintenance for your tools to ensure their longevity and optimal performance, which can save time and reduce costs in the long run.

By embracing automatic tools, artisans can also increase their production capacity. This means being able to take on larger orders or experiment with more intricate designs without the fear of compromising quality. The combination of creativity and technology encourages artisans to push their boundaries and explore new avenues in jewelry design.

The jewelry making process has undergone a remarkable transformation with the advent of innovative technologies that cater to artisans of all skill levels. Automatic tools are now integrated into traditional crafting practices, enhancing precision and efficiency. Advanced machinery such as 3D printers and laser cutters allow artisans to create intricate designs that were once labor-intensive and time-consuming. These tools not only streamline the production process but also open up new avenues for creativity, enabling jewelers to explore complex geometries and customizable options that appeal to a diverse clientele.

Moreover, software applications designed specifically for jewelry design have revolutionized the way artisans conceptualize their work. With intuitive interfaces, these programs enable creators to visualize their designs in a virtual environment before moving to production. This not only reduces material waste but also fosters a collaborative approach to design, allowing for quick modifications and client feedback. As technology continues to advance, it empowers artisans to push the boundaries of traditional jewelry making, leading to unique creations that reflect both personal style and cutting-edge innovation.

The introduction of automatic tools in jewelry making has significantly transformed the landscape for artisans, enhancing both creativity and efficiency. With the integration of advanced technology, jewelers can now explore intricate designs that were once deemed too complex or time-consuming. Automated systems allow for precision in tasks such as engraving, stone setting, and casting, enabling artisans to push the boundaries of their craft. As a result, creativity flourishes when the burden of repetitive tasks is lifted, allowing jewelers to focus on innovation and artistic expression.

Moreover, the efficiency gained through automatic tools streamlines the production process, facilitating faster turnaround times without sacrificing quality. Artisans can quickly adapt their designs based on market trends or customer feedback, leading to greater responsiveness in their businesses. This dynamic approach not only satisfies clients’ evolving tastes but also empowers jewelers to experiment with new techniques and materials. Consequently, the fusion of creativity and technology not only enhances the individual artisan’s capabilities but also encourages the growth and sustainability of the jewelry industry as a whole.

The world of jewelry making is experiencing a significant transformation, merging traditional craftsmanship with cutting-edge automation. According to a recent report by Gartner, the global market for automated tools in artisan industries is expected to grow by 22% over the next five years. This represents a pivotal shift for makers, as they seek to enhance their productivity while maintaining the unique, handcrafted essence of their creations. Incorporating automated tools enables artisans to streamline repetitive tasks, allowing them to focus on design and innovation, which are essential for staying competitive in a rapidly evolving market.

Moreover, balancing tradition and modernization is crucial in the jewelry sector. A survey conducted by Statista found that 63% of consumers prefer products that reflect both artisanal craftsmanship and modern manufacturing techniques. Artisans can achieve this balance by integrating tools that enhance precision without sacrificing their creative touch. For example, the use of 3D printing technology not only allows for intricate designs that would be time-consuming by hand, but it also preserves the artisanal nature of the final product. As the jewelry industry continues to embrace automation, artisans can cultivate a new era of creativity, where traditional skills meet innovative methodologies, ensuring that fine jewelry remains both timeless and contemporary.