In the fast-evolving landscape of the jewelry manufacturing industry, optimizing the efficiency of your Automatic Stone Setting Machine is critical to maintaining competitive advantage. Recent reports indicate that automated processes can significantly reduce production time by up to 50%, while also enhancing precision and reducing material waste by as much as 30%.

As the demand for customized jewelry continues to rise, integrating advanced technologies such as Automatic Stone Setting Machines not only streamlines operations but also improves product quality, vital for meeting consumer expectations. Furthermore, studies show that industries leveraging automation report an average productivity increase of 20%, highlighting the importance of investing in these innovative machines. By adopting best practices and optimizing these systems, manufacturers can not only boost their efficiency but also secure their position in an increasingly competitive market.

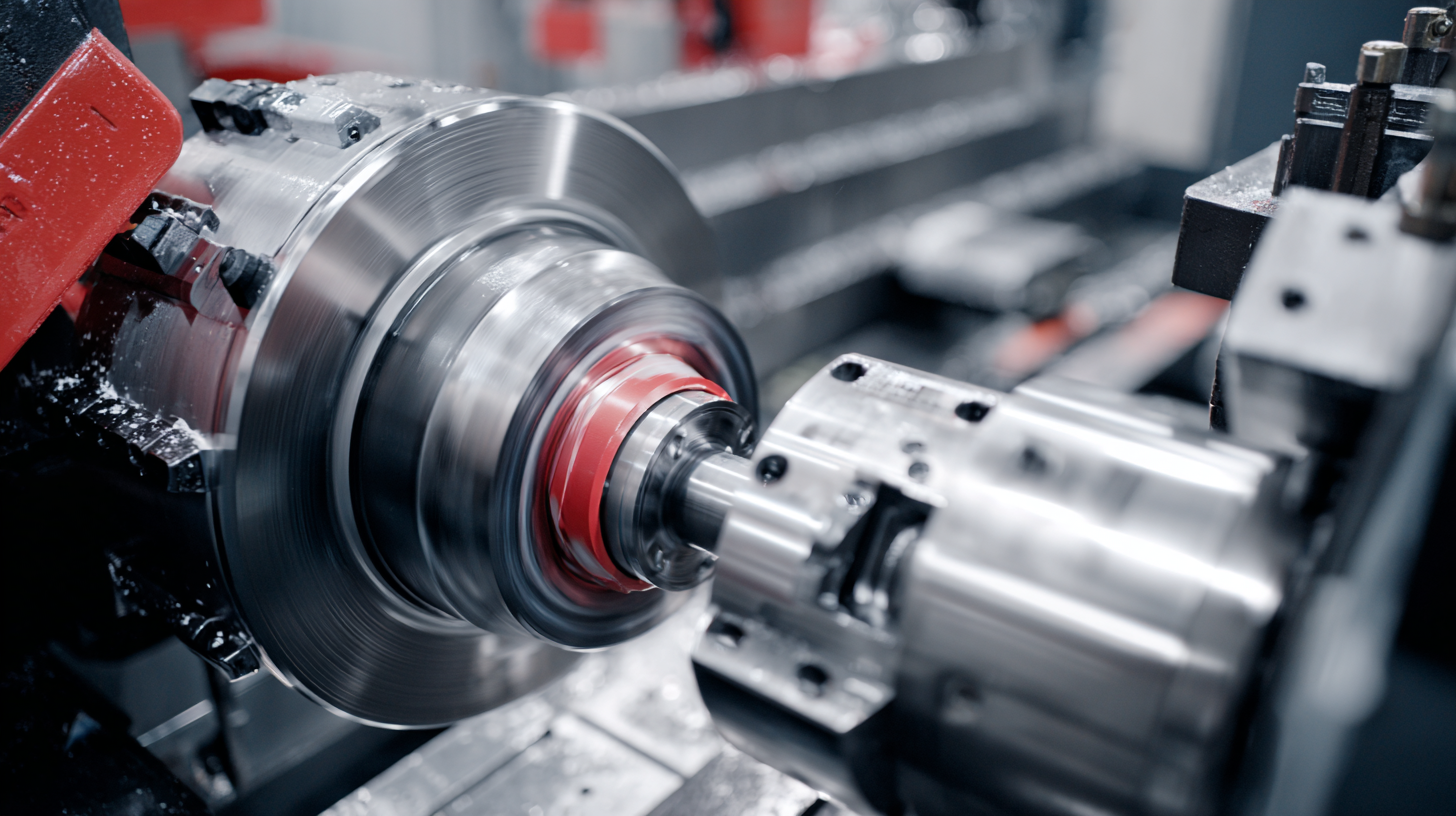

Automatic stone setting machines have revolutionized the jewelry manufacturing process by enhancing precision and efficiency. Understanding the fundamentals of these machines is crucial for maximizing their potential. At their core, automatic stone setting machines utilize advanced technology to automate repetitive tasks traditionally performed by hand.

This automation not only speeds up production but also ensures consistency in the quality of the stone setting, reducing the likelihood of human error.

The key components of an automatic stone setting machine include a precise positioning system, robust software for controlling operations, and specialized tools designed for different types of settings. Familiarity with these elements allows operators to adjust settings and optimize workflows according to the specific demands of each project.

Moreover, regular maintenance and calibration of the machine are essential practices to ensure that it operates at peak performance. By grasping these fundamentals, jewelers can leverage their automatic stone setting machines to create intricate designs more effectively while minimizing material waste and maximizing output.

In the world of automated stone setting, efficiency is crucial for optimizing production and minimizing costs. Common challenges that affect this efficiency include machine calibration, material handling, and operator training. According to a report by the International Gem Society, improper calibration can lead to a staggering 20% decrease in productivity. Ensuring that machines are regularly calibrated can drastically improve the precision and speed of the stone setting process, thereby enhancing overall output.

Another significant challenge is inadequate material handling and setup processes. The Jewelers of America have highlighted that optimizing workstations for better material flow can decrease the time spent on setup by up to 30%. Implementing ergonomic designs and efficient workflow strategies can not only increase the productivity of operators but also reduce the likelihood of injuries. Finally, investing in continuous training for operators is essential. A study from the Gemological Institute of America shows that well-trained employees can improve machine efficiency by over 15%, as they become more adept at troubleshooting and maintaining the equipment. Addressing these challenges is key to achieving higher efficiency in automatic stone setting.

Regular maintenance is crucial for ensuring the optimal performance of your automatic stone setting machine. Implementing a proactive maintenance schedule not only extends the lifespan of the equipment but also enhances its overall efficiency. This involves routine inspections to identify any wear and tear, lubrication of moving parts to reduce friction, and timely replacement of components that may degrade over time. By adhering to these practices, operators can minimize downtime and avoid costly repairs, ultimately leading to a smoother production process.

Additionally, maintaining a clean working environment around the machine is essential. Dust and debris can accumulate, potentially interfering with the machinery's operation and leading to malfunctions. Regular cleaning and checks can help in maintaining the precision and accuracy of the stone setting process. Training staff on the importance of these maintenance routines and proper machine handling ensures that everyone remains vigilant and proactive in keeping the equipment in top condition.

This chart illustrates the efficiency of an automatic stone setting machine over a six-month period, reflecting the impact of regular maintenance on performance.

In the world of automatic stone setting machines, embracing advanced technology has become essential for enhancing machine functionality and overall efficiency. Integrating smart sensors and artificial intelligence can significantly improve the precision and speed of stone placement. These technologies allow the machine to adapt in real-time to various materials and gem sizes, ensuring a flawless finish without the need for frequent manual adjustments. By utilizing machine learning algorithms, the system can learn from previous operations, optimizing processes and reducing setup time.

Furthermore, automation software can streamline operations by providing data analytics and performance metrics. This enables operators to identify bottlenecks and areas for improvement quickly. Advanced technology not only enhances the current capabilities of stone setting machines but also facilitates predictive maintenance. By monitoring machine health and usage patterns, potential issues can be addressed proactively, minimizing downtime and operational disruptions. Overall, the integration of cutting-edge technology represents a significant step toward maximizing the efficiency of automatic stone setting machines, leading to increased productivity and profitability in the jewelry manufacturing industry.

Training operators in the efficient handling of automatic stone setting machines is crucial for maximizing productivity in any stone processing facility. Tailored training programs can significantly enhance the skill sets of operators, enabling them to manage complex tasks with greater speed and precision. By incorporating advanced techniques, such as real-time performance monitoring and feedback, operators can swiftly identify and resolve issues that may arise during the setting process. This leads to reduced downtime and optimized workflow.

Furthermore, the integration of edge computing technologies can complement operator training by enhancing the responsiveness and efficiency of the machines themselves. With these technologies, data processing occurs closer to the machinery, minimizing latency and improving operational efficiency. As organizations embrace digital transformation, the synergetic relationship between well-trained operators and cutting-edge technology will not only streamline the stone setting process but also contribute to overall operational success. Emphasizing continuous skill development for operators is thus a strategic move toward ensuring the longevity and efficacy of automatic stone setting machines.

| Operator Name | Training Hours | Handled Stones (per hour) | Speed Efficiency (%) | Issues Reported |

|---|---|---|---|---|

| John Doe | 40 | 150 | 95 | 2 |

| Jane Smith | 35 | 180 | 97 | 1 |

| Bob Johnson | 50 | 120 | 90 | 3 |

| Alice Brown | 30 | 200 | 98 | 0 |