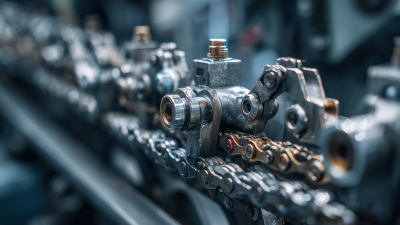

The Automatic Chain Hammer Machine has become an essential tool in various industries, especially in manufacturing and construction, due to its efficiency and precision. According to a recent market analysis, the demand for automated machinery, including chain hammer machines, is projected to grow by 8.5% annually, driven by the need for increased productivity and reduced labor costs. This surge in demand highlights the importance of optimizing the use of such machines. By leveraging innovative practices and techniques, businesses can significantly enhance the performance and longevity of their Automatic Chain Hammer Machines. In this context, understanding the best practices not only improves output but also minimizes maintenance costs, allowing companies to stay competitive in a fast-paced market.

Investing in automatic chain hammer machines can significantly enhance productivity across various industries. These machines are designed to operate with minimal human intervention, streamlining processes that once required extensive manual labor. By automating tasks such as hammering and securing, businesses can reduce downtime and optimize workflow. This not only speeds up production times but also ensures consistent quality, as automated processes reduce the likelihood of human error.

Additionally, the long-term benefits of these machines extend beyond immediate productivity gains. By decreasing labor costs and increasing output, companies can ultimately boost their profit margins. Automatic chain hammer machines also allow for better scalability; as demand increases, businesses can rely on these machines to ramp up production without the need for significant additional resources. The investment in automation reflects a commitment to innovation, positioning companies to remain competitive in an evolving market.

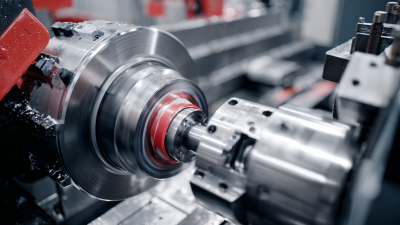

To achieve optimal efficiency in automatic chain hammer operations, understanding the machine's settings is crucial. Different operational modes can significantly impact performance. For instance, utilizing a speed mode might enhance throughput, but it can also lead to performance dips if not calibrated correctly, especially under high-load conditions. Properly adjusting the frequency and impact force settings based on the material being processed can ensure that the machine operates effectively without unnecessary strain.

Further optimization can arise from leveraging data-driven strategies akin to those seen in various industrial applications. Monitoring operational conditions and adjusting settings in real-time can minimize downtime and waste. For example, implementing advanced analytics can help predict the optimal settings for different materials, similar to how businesses utilize artificial intelligence to streamline operations. By continuously assessing the machine's performance and making fine-tuned adjustments, users can maximize productivity while maintaining high-quality output.

| Tip | Optimal Setting | Expected Efficiency Gain (%) | Maintenance Frequency (Hours) |

|---|---|---|---|

| 1. Optimize Hammer Speed | 800-1000 RPM | 15% | 100 |

| 2. Adjust Chain Tension | Optimal Tension Level | 10% | 50 |

| 3. Monitor Lubrication System | Regular Checks | 8% | 30 |

| 4. Configure Proper Materials | Material Compatibility | 20% | 80 |

| 5. Calibrate Equipment Regularly | Quarterly Calibration | 12% | 200 |

| 6. Train Operators Effectively | Regular Training Sessions | 25% | N/A |

| 7. Utilize Real-time Monitoring | Real-time Data Analysis | 30% | N/A |

Regular maintenance practices significantly influence the longevity and output of automatic chain hammer machines, ultimately impacting operational efficiency. According to a report by the Machinery Maintenance Institute, routine maintenance can extend machinery life by up to 30% compared to machines that receive minimal care. This is particularly important for chain hammer machines, which are subject to high wear and tear during operation. Neglected maintenance can lead to increased downtime, reduced productivity, and costly repairs that can easily be avoided through proactive care.

Additionally, the output quality of chain hammer machines is closely tied to their maintenance regimen. A study published in the Journal of Manufacturing Processes revealed that well-maintained machines can produce up to 15% more output, thanks to consistent operational performance. Regular checks on key components, such as hammers and attachments, ensure that the machine runs smoothly and minimizes the risk of breakdowns. Implementing a structured maintenance schedule not only enhances productivity but also ensures that the machines operate within optimal parameters, maintaining the desired output quality over time.

In the realm of automatic chain hammer systems, energy consumption is a critical factor that influences both operational costs and efficiency. Recent analyses have shown that fully automated warehouse technologies can reduce energy consumption by up to 30% compared to manual systems. This reduction not only leads to significant cost savings but also minimizes the environmental impact of manufacturing processes. A techno-economic assessment reveals that the integration of energy-efficient components in automatic chain hammer machines can optimize overall energy usage, further enhancing sustainability.

Moreover, the application of artificial intelligence in manufacturing processes is revolutionizing energy management. AI has the potential to analyze real-time data on energy consumption patterns, leading to more informed decision-making and the identification of inefficiencies. Reports indicate that AI-driven optimization strategies can increase operational efficiency by 15-20% in manufacturing environments. As manufacturers seek to comply with global sustainability goals, understanding and optimizing energy consumption trends in automatic chain hammer systems becomes imperative for cost-effective operations and future innovation.

Leveraging data analytics can significantly enhance the performance of automatic chain hammer machines, transforming them into more efficient production tools. By collecting and analyzing operational data, manufacturers can gain valuable insights into machine behavior, maintenance needs, and production bottlenecks. This data-driven approach allows for real-time monitoring, enabling swift adjustments to optimize machine settings, which can lead to reduced downtime and improved output quality.

Leveraging data analytics can significantly enhance the performance of automatic chain hammer machines, transforming them into more efficient production tools. By collecting and analyzing operational data, manufacturers can gain valuable insights into machine behavior, maintenance needs, and production bottlenecks. This data-driven approach allows for real-time monitoring, enabling swift adjustments to optimize machine settings, which can lead to reduced downtime and improved output quality.

Moreover, predictive analytics plays a crucial role in revolutionizing maintenance strategies. By analyzing patterns and trends in machine performance, manufacturers can proactively address potential issues before they lead to costly breakdowns. This not only saves time and reduces repair costs but also extends the lifespan of the equipment. As a result, businesses can maintain a smooth production flow, ensure product consistency, and ultimately enhance their competitiveness in the market. Integrating data analytics into the operation of chain hammer machines is thus an essential strategy for maximizing efficiency and driving growth.