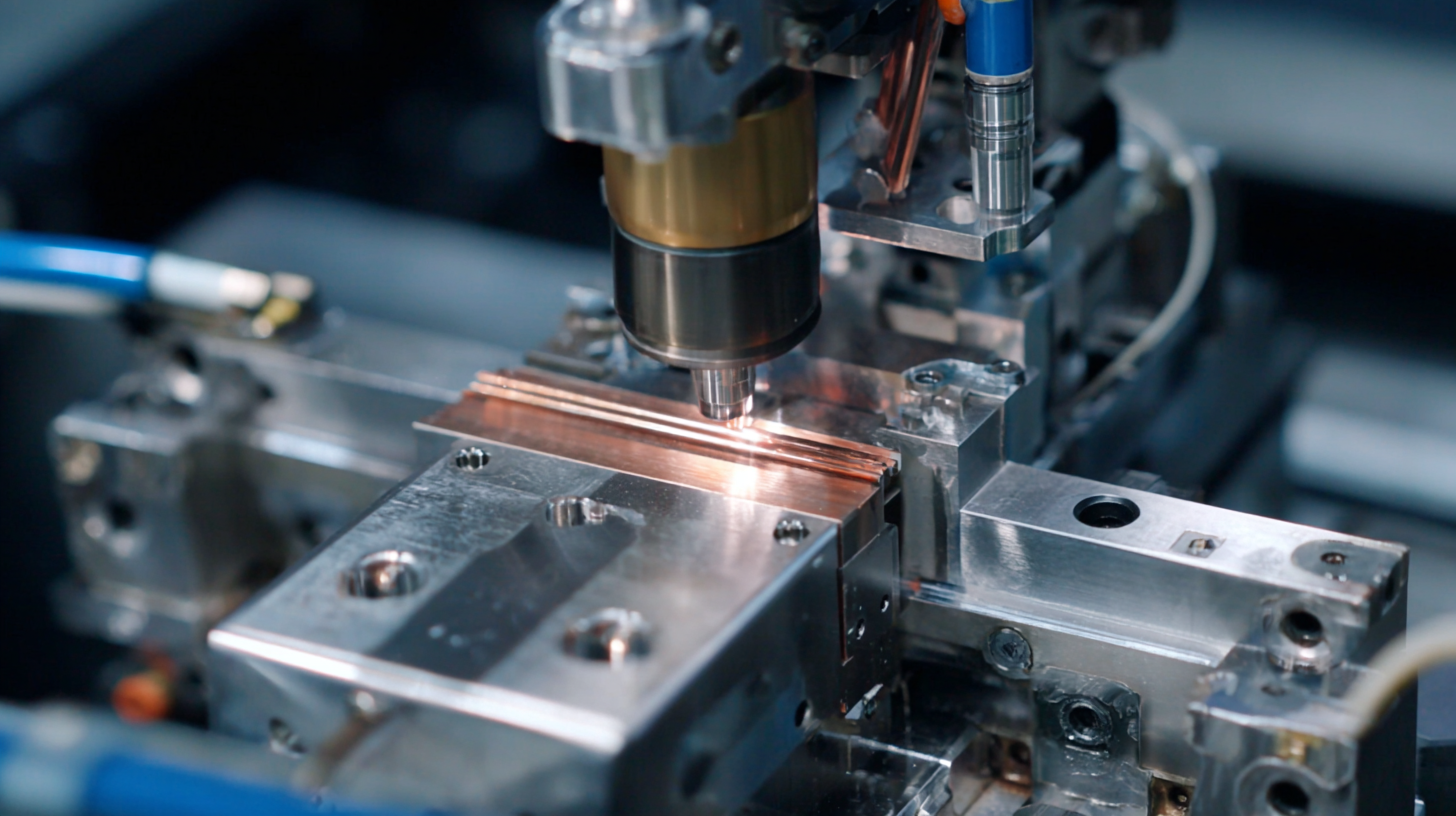

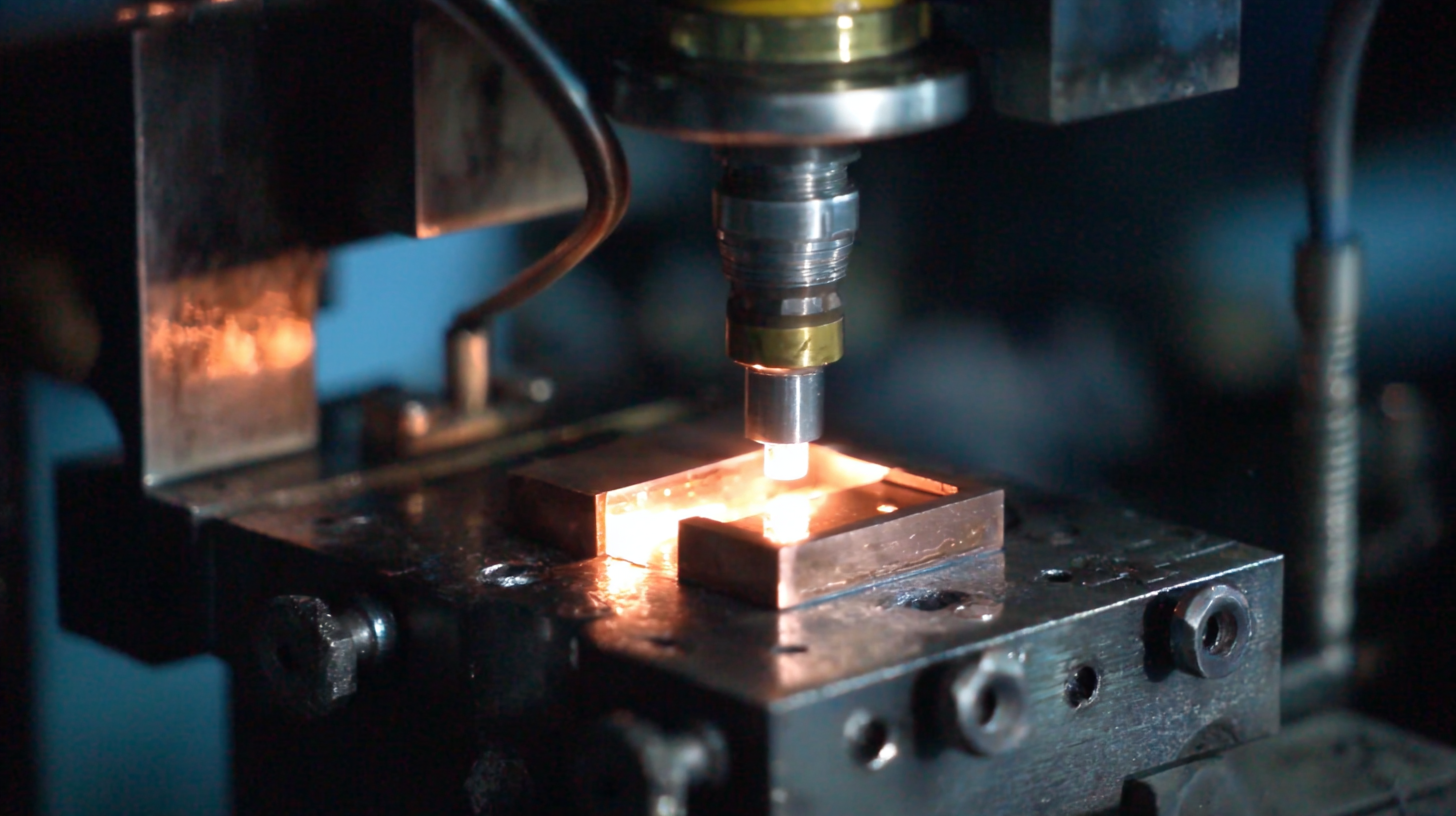

In the competitive world of jewelry manufacturing, the success of your business often hinges on the quality and reliability of your equipment, particularly when it comes to the Electroforming Jewelry Machine. Mastering the intricacies of import and export certification can be a game-changer, allowing artisans to leverage superior Chinese manufacturing capabilities to create intricate and high-quality jewelry pieces that cater to a global market. With the mantra “精工细造,中国制造,服务世界” resonating at the core of this process, every step towards compliance not only enhances product quality but also opens doors to international trade opportunities.

In this blog, we will explore the essential steps in obtaining the necessary certifications for your Electroforming Jewelry Machine, ensuring that your creations not only meet industry standards but also stand out in a world that values excellence and innovation.

Understanding the nuances of import export certification is crucial for businesses engaged in the electroforming jewelry machine industry. These certifications facilitate the smooth movement of machinery and materials across borders, ensuring compliance with international regulations. For manufacturers and exporters of electroforming machines, obtaining the right certifications not only boosts credibility but also opens up new markets. Navigating the certification process requires a comprehensive understanding of both local and international standards related to machinery safety, environmental impact, and product quality.

Additionally, the complexities involved in the import export certification process can often be daunting. It is essential to stay informed about the latest regulations and to collaborate with experienced professionals who can guide businesses through the required documentation and procedures. By investing time in mastering this aspect of business operations, companies can enhance their competitiveness, reduce delays in shipping, and ultimately achieve greater success in the global marketplace for electroforming jewelry machines. This knowledge not only aids in compliance but also fosters better relationships with customs and regulatory bodies, paving the way for smoother transactions.

In the competitive realm of electroforming jewelry, obtaining certification offers numerous advantages that cannot be overlooked. The GIA’s recent move to certify gold and studded jewelry enhances buyer confidence, ensuring that both domestic and export markets are treated with the utmost professionalism. Certification acts as a seal of quality, providing consumers with reassurance about the authenticity and value of their purchases. This also aligns with the growing importance of ethical practices in the jewelry industry, as consumers increasingly seek transparency in sourcing and production.

Tips:

To navigate the certification process effectively, jewelers should begin by familiarizing themselves with the various certification bodies and their requirements. Engaging in educational programs can enhance understanding and compliance. Additionally, embracing innovations, such as blockchain technology, can bolster supply chain transparency, further solidifying consumer trust in certified products.

Investing time in accreditation not only helps to elevate a jeweler's brand but also opens doors to potential federal funding and tax credits, especially for those adopting new curricula, like the MJSA apprenticeship program. The commitment to quality through certification can ultimately lead to significant long-term benefits, transforming small businesses into trusted players in the jewelry market.

Navigating the import-export certification process for electroforming jewelry machines can be daunting, but a structured approach can significantly simplify it. According to a report by IBISWorld, the electroforming machinery market is projected to grow by 4.2% annually, making it essential for businesses to ensure compliance with international regulations to maintain competitiveness. This guides you through the critical steps involved in obtaining necessary certifications.

First, familiarize yourself with the specific standards required in your target market, such as ISO certifications or CE markings. Conduct thorough research on the regulations governing the import and export of machinery in key regions, as these can differ significantly. Documentation is vital—ensure all safety and quality assurance certificates are organized and up-to-date.

Tip: Partnering with a certification consultant can expedite the process and help you avoid common pitfalls. Additionally, consider participating in industry workshops, which can provide valuable insights into best practices and networking opportunities.

Once you have compiled the necessary documentation, the next step is to submit your application to the appropriate regulatory bodies. Track the application progress and be prepared for any inquiries or additional documentation requests.

Tip: Keeping a checklist of requirements will help you stay organized and ensure that you don’t miss any critical steps in the process. Engaging with existing certified companies can also provide guidance and practical insights that benefit your certification journey.

Navigating the complexities of import-export certification can be daunting, especially in the electroforming jewelry machine industry. A recent report by Market Research Future indicates that the global electroforming market is expected to grow at a CAGR of 6.5% from 2021 to 2027, underscoring the importance of compliance for manufacturers looking to expand their global reach. One significant challenge is the ever-evolving regulatory landscape—importers must stay abreast of changes in international standards, which can vary significantly between regions. Misunderstanding these regulations can lead to costly delays or compliance failures.

Another common hurdle is the financial burden associated with certification processes. According to a survey by the International Trade Centre, over 30% of small to medium enterprises (SMEs) cited costs related to compliance as a major barrier to international trade. However, investing in a dedicated compliance team and utilizing consultancy services can streamline the process, ensuring that businesses not only comply but thrive in foreign markets. Furthermore, leveraging digital solutions can enhance document management and tracking, reducing the time and resources spent on certification. Addressing these challenges effectively can lead to a more successful entry into the competitive landscape of the electroforming jewelry industry.

| Challenge | Impact | Solutions | Outcome |

|---|---|---|---|

| Regulatory Compliance | Potential fines and legal issues | Regular training and updates | Reduced legal risks |

| Documentation | Delays in shipment | Implement a document checklist | Faster clearance times |

| Cost Management | Increased operational costs | Budget planning and audits | Improved cost efficiency |

| Supplier Relations | Disruption in supply chain | Regular communication and feedback | Stable supply chain |

| Market Changes | Loss of market competitiveness | Market analysis and forecasting | Increased market adaptability |

When it comes to scaling your electroforming jewelry business, investing in certified equipment can make a world of difference. The benefits of using certified electroforming machinery extend beyond compliance with industry standards; they significantly enhance operational efficiency and product quality. Certified machines are typically designed to meet rigorous safety and performance benchmarks, ensuring that your production process runs smoothly. This reliability not only boosts productivity but also minimizes downtime due to equipment-related issues.

Moreover, certified equipment can elevate your brand’s reputation in the competitive jewelry market. Customers today are increasingly discerning and often look for transparency in production practices. By using certified electroforming machines, you demonstrate a commitment to quality and safety, which can foster trust and loyalty among your clientele. This reputation for excellence can set you apart from competitors, ultimately leading to increased sales and sustained business growth. Embracing certified technology is not just a choice for compliance; it is a strategic move that aligns your operations with best practices in the industry, promoting long-term success.