As the global jewelry industry continues to evolve, the introduction of cutting-edge technology is revolutionizing traditional craftsmanship. According to industry reports, the automatic jewelry making machine market is projected to witness a remarkable growth, with estimates indicating a CAGR of over 15% from 2022 to 2025. This substantial increase can be attributed to advancements in automation, which enhance efficiency and reduce production costs while maintaining high-quality standards.

For buyers worldwide, mastering the best automatic jewelry making machine is not only crucial for staying competitive but also for meeting the rising demand for personalized and intricate designs that consumers now expect. This comprehensive tutorial aims to equip global buyers with the insights necessary to navigate the complexities of selecting and utilizing these innovative machines effectively, ensuring they can capitalize on the promising trends shaping the future of the jewelry industry.

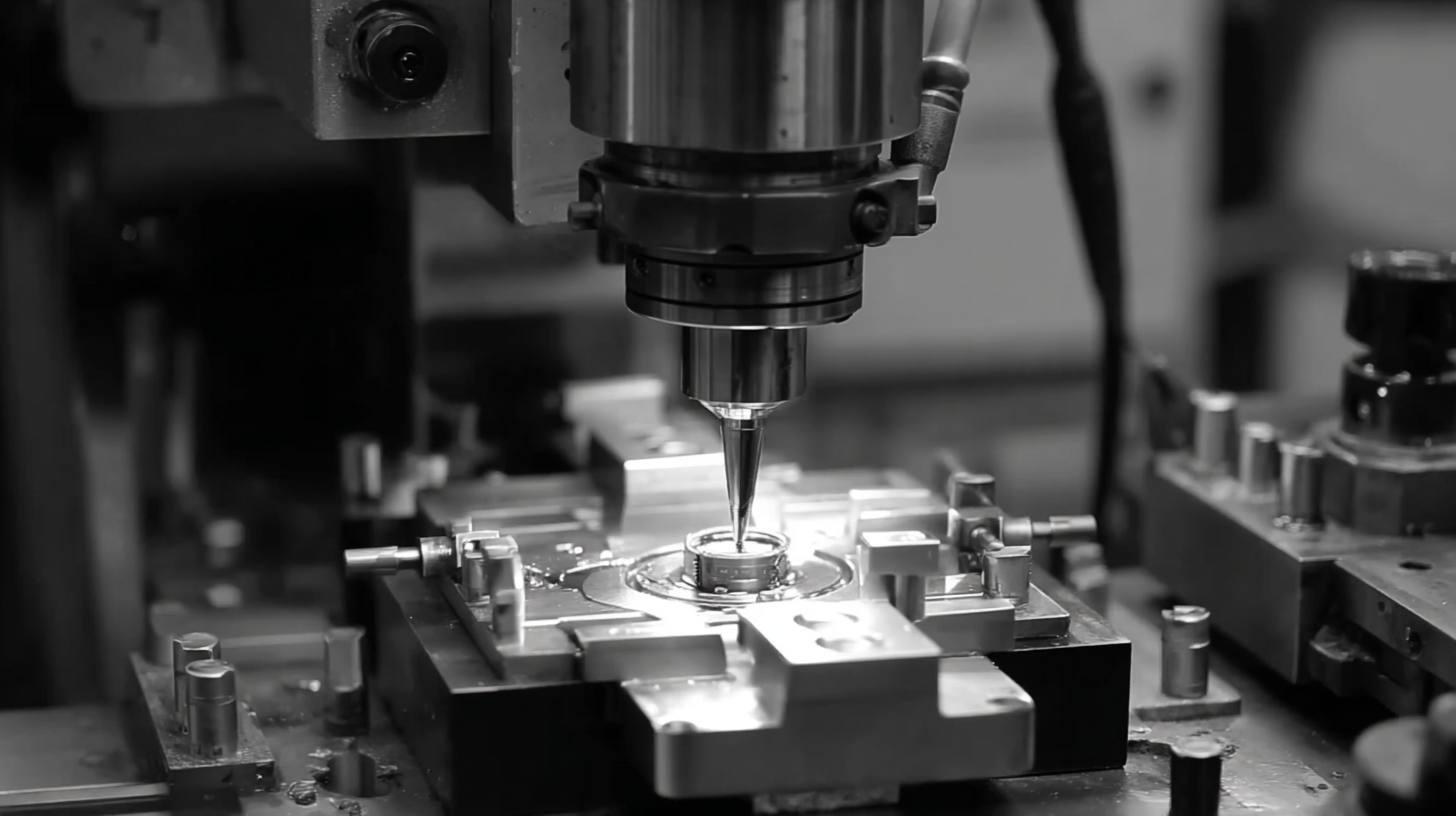

Automatic jewelry making machines have revolutionized the way jewelry is produced by enhancing efficiency and precision in modern production. One of the key benefits of these machines is their ability to execute intricate designs consistently, reducing the chances of human error. This precision results in a higher quality finished product, allowing artisans to focus on creativity rather than repetitive tasks. By streamlining the manufacturing process, these machines enable jewelers to scale their operations and meet growing market demands without compromising on quality.

Additionally, automatic jewelry making machines significantly reduce production time. Traditional jewelry-making methods can be time-consuming, but automation allows for faster turnaround times, making it possible for businesses to respond quickly to customer requests and market trends. This increased speed not only boosts productivity but also ensures that jewelers can offer competitive pricing without sacrificing craftsmanship. As a result, investments in automatic jewelry making machines pay off by enhancing overall profitability for manufacturers in the global jewelry industry.

| Feature | Description | Benefits | Price Range (USD) |

|---|---|---|---|

| Automated Production | Machines that automate various stages of jewelry manufacturing | Increased efficiency and consistent quality | $2,000 - $15,000 |

| User-Friendly Interface | Intuitive controls and programming options | Easier for workers to operate, reducing training time | $1,500 - $12,000 |

| Versatility | Able to produce a variety of jewelry types | Ability to cater to diverse customer preferences | $3,000 - $20,000 |

| Precision Engineering | High accuracy in manufacturing processes | Reduces material waste and improves product quality | $4,000 - $25,000 |

| Maintenance Features | Built-in diagnostics and alerts for maintenance | Minimizes downtime and prolongs machine life | $2,500 - $18,000 |

When selecting an automatic jewelry making machine, buyers should pay close attention to several key features that can significantly impact production quality and efficiency. According to a recent industry report by Smithers Pira, the global jewelry manufacturing market is expected to grow at a CAGR of 5.6% between 2021 and 2026, emphasizing the need for reliable machinery that can keep up with rising demand. High-precision features, such as laser welding and 3D printing capabilities, have become essential in modern jewelry production, allowing manufacturers to create intricate designs with less material waste while maintaining excellent finishing quality.

Moreover, automation and user-friendly interfaces are increasingly important in choosing the right equipment. Machines equipped with programmable features streamline the design process and improve consistency across products. A 2020 survey by the Jewelry Consumer Opinion Council found that 74% of manufacturers reported an increase in productivity after investing in advanced manufacturing technology. Thus, prospective buyers should prioritize equipment that offers seamless integration with design software and enhances workflow efficiency, ensuring they remain competitive in the evolving jewelry market.

When embarking on the journey of purchasing an automatic jewelry making machine, it is essential to clarify your needs before diving into the plethora of options available. Start by identifying the specific types of jewelry you wish to create. Are you focused on intricate designs, or do you prefer simpler, more streamlined production? Understanding your niche will guide you in selecting a machine designed to meet those specific requirements, ensuring efficiency and satisfaction in your crafting process.

Next, consider the scale of your production. If you are a hobbyist, a compact, user-friendly machine might suffice, while a larger investment may be necessary for professional manufacturers seeking to produce high volumes with precision and speed. Additionally, pay attention to the machine's features such as programmable settings, ease of maintenance, and the availability of customer support. Evaluating these factors thoroughly will enable you to make an informed decision, ensuring that the machine you choose aligns with your creative vision and operational goals in the dynamic world of jewelry making.

This bar chart displays the production capacity (units per hour) of various types of automatic jewelry making machines. Understanding these capacities can help buyers choose the right machine to meet their needs.

In the competitive landscape of jewelry making, the choice of an automatic jewelry making machine is pivotal. Recent market research indicates that the demand for such machines is projected to grow significantly, fueled by advancements in laser welding technology. The laser welding market is anticipated to reach substantial figures by 2029, with a compound annual growth rate (CAGR) benefiting from increased applications across various sectors, including jewelry manufacturing.

A comparative analysis of leading automatic jewelry machines reveals a diverse range of features tailored for different production needs. Machines utilizing conduction and deep penetration welding modes offer distinct advantages in efficiency and precision. Technologies like fiber and CO2 lasers are particularly favored for their versatility and ability to produce high-quality welds on intricate designs. According to recent data, the proliferation of solid-state lasers is also reshaping the market, promising enhanced performance and reliability.

As global buyers seek the best automatic jewelry making machines, understanding the dynamics of the market and the capabilities of various technologies becomes essential. Each machine's specifications, backed by rigorous industry analysis, serve as a roadmap for making informed decisions that align with both production requirements and budget constraints.

The global jewelry manufacturing industry is experiencing unprecedented growth, driven largely by advancements in technology and the demand for customization. According to a report by Mordor Intelligence, the global jewelry market is expected to reach approximately $480 billion by 2025, with a significant portion attributed to automated jewelry making machines. This shift toward automation not only enhances production efficiency but also addresses the growing consumer expectation for unique and personalized designs.

Navigating the complexities of the global supply chain is essential for buyers of premium jewelry manufacturing solutions. The integration of automatic jewelry making machines allows manufacturers to streamline operations, reduce lead times, and mitigate costs. Forbes highlights that companies employing advanced manufacturing technologies can reduce operational costs by up to 30%, a compelling advantage in a highly competitive market. As a result, investing in these machines is becoming increasingly attractive for businesses aiming to remain relevant in a dynamic economic landscape. By understanding the intricacies of the supply chain and leveraging cutting-edge machinery, manufacturers can enhance their product offerings and meet the evolving demands of global consumers.