The jewelry manufacturing industry is undergoing a transformative phase, driven by advancements in technology and innovative practices. One of the most significant developments is the introduction of the Electroforming Jewelry Machine, which has become a game-changer in the production of intricate and lightweight designs.

According to a recent industry report by Grand View Research, the global jewelry market is projected to reach USD 292.5 billion by 2025, with a growing demand for customization and unique designs fueling this growth. The electroforming process allows jewelers to create highly detailed pieces with fine craftsmanship while minimizing material waste, aligning with the increasing emphasis on sustainability in manufacturing. As the market evolves, the flexibility and efficiency of Electroforming Jewelry Machines are positioning them as essential tools for modern jewelers aiming to meet consumer demands and stay competitive in a fast-paced industry.

According to a recent industry report by Grand View Research, the global jewelry market is projected to reach USD 292.5 billion by 2025, with a growing demand for customization and unique designs fueling this growth. The electroforming process allows jewelers to create highly detailed pieces with fine craftsmanship while minimizing material waste, aligning with the increasing emphasis on sustainability in manufacturing. As the market evolves, the flexibility and efficiency of Electroforming Jewelry Machines are positioning them as essential tools for modern jewelers aiming to meet consumer demands and stay competitive in a fast-paced industry.

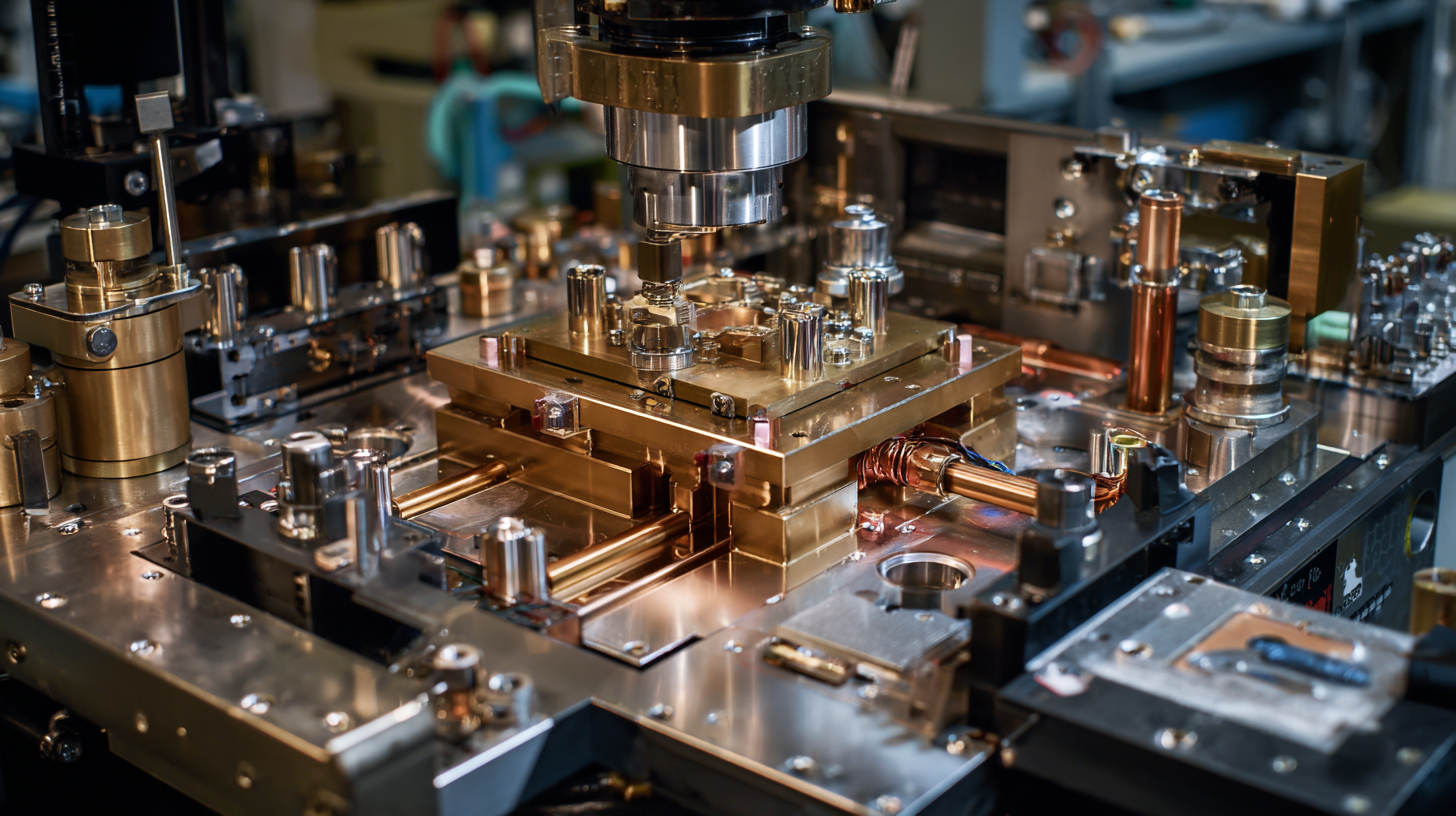

Electroforming jewelry is an innovative process that has transformed the way jewelry is manufactured. This technique involves the deposition of metal onto a model to create intricate designs, allowing for a high degree of detail and customization that traditional methods may struggle to achieve. Understanding the principles and processes of electroforming is crucial for jewelry designers looking to push the boundaries of creativity while maintaining efficiency and sustainability.

Recent advancements in eco-friendly jewelry design have highlighted the importance of integrating technology, such as artificial neural networks, to optimize designs for sustainability. As the industry moves towards more responsible practices, adopting advanced electroforming techniques can further enhance eco-conscious manufacturing processes. The application of such methods not only addresses environmental concerns but also offers a pathway for brands to innovate and differentiate themselves in a competitive market. By leveraging these modern technologies, jewelers can create stunning works that resonate with consumers who value both artistry and sustainability.

| Aspect | Details |

|---|---|

| Electroforming Principle | A process that uses electrolysis to deposit metal onto a model to create a durable and intricate form. |

| Materials Used | Common materials include gold, silver, and copper for their aesthetic properties and conductivity. |

| Advantages | Allows for complex designs, reduces material waste, and provides a smooth surface finish. |

| Current Trends | Increased adoption in custom jewelry, emphasis on sustainability, and integration with digital design technologies. |

| Market Growth | The electroforming jewelry market is expected to grow significantly, driven by technological advancements and consumer demand for personalized items. |

| Future Outlook | Continued innovation in electroforming machines and materials is likely, enhancing production speed and design capability. |

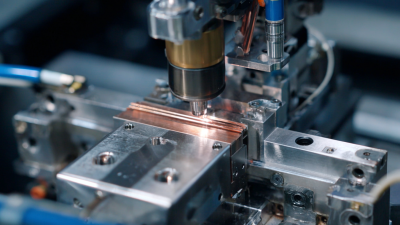

Advanced electroforming machines are transforming the jewelry manufacturing landscape, providing significant advantages over traditional methods. Key features to look for in these machines include precision control, scalability, and energy efficiency. The precision control allows for detailed customization and intricate designs, which are essential for high-end jewelry production. Furthermore, scalability enables manufacturers to adjust production volumes easily, catering to both small and large-scale demands without compromising quality.

Advanced electroforming machines are transforming the jewelry manufacturing landscape, providing significant advantages over traditional methods. Key features to look for in these machines include precision control, scalability, and energy efficiency. The precision control allows for detailed customization and intricate designs, which are essential for high-end jewelry production. Furthermore, scalability enables manufacturers to adjust production volumes easily, catering to both small and large-scale demands without compromising quality.

The electroplating equipment market has shown promising growth, estimated at USD 802.85 million and projected to reach USD 1315.46 million by 2030, with a compound annual growth rate (CAGR) of 6.37%. This trend indicates an increasing reliance on advanced technologies in jewelry manufacturing. As companies seek more sustainable and durable options, features such as eco-friendly processes and improved cycle times in electroforming machines are becoming vital. Manufacturers must stay informed about these technological advancements to remain competitive in a rapidly evolving marketplace.

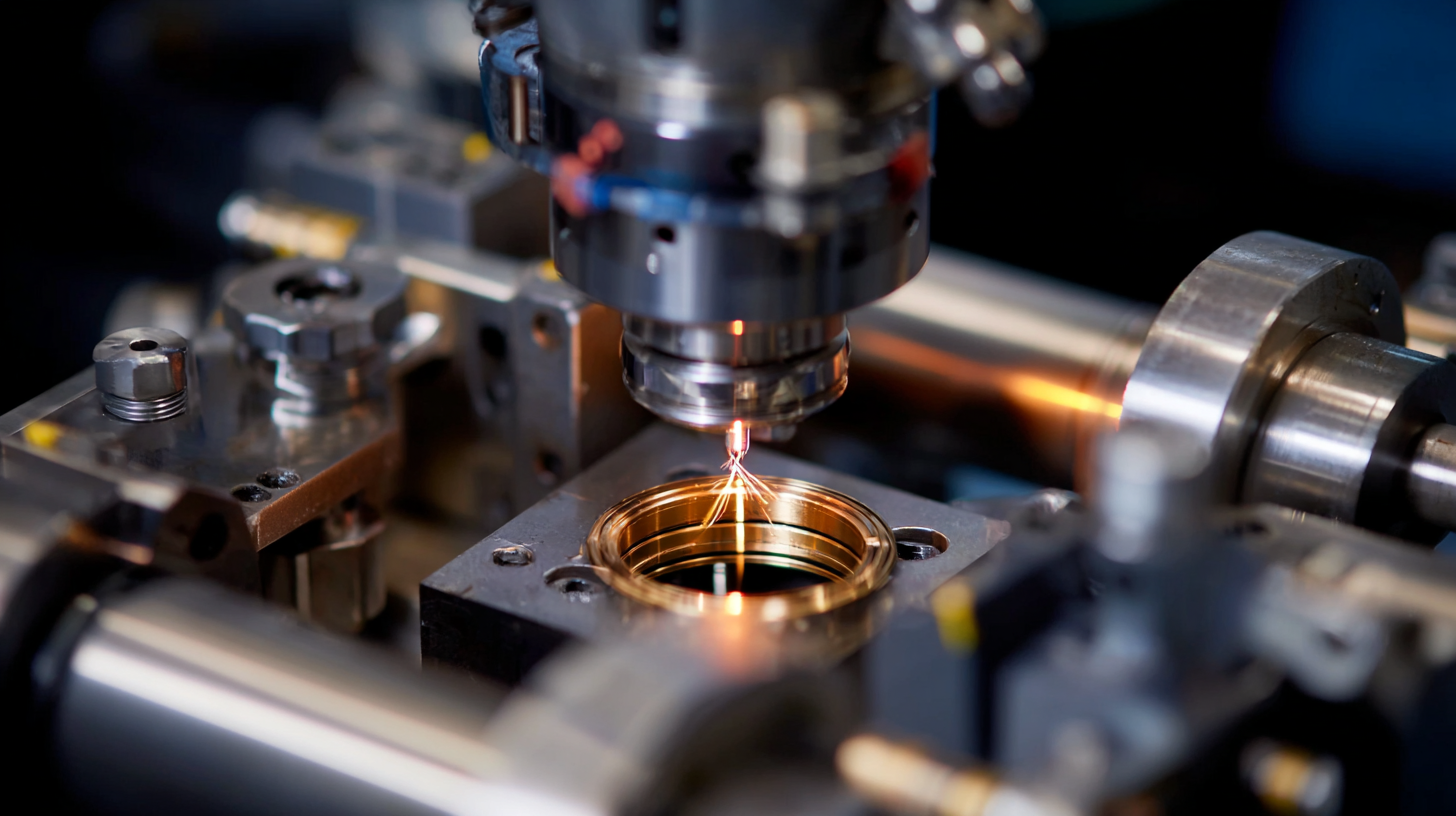

The jewelry manufacturing industry is experiencing a significant transformation driven by innovative trends and advanced technologies, particularly in electroforming. According to a recent report by Grand View Research, the global jewelry market size is expected to reach USD 480.5 billion by 2025, with electroforming technology playing a crucial role in enhancing manufacturing efficiency and lowering production costs. This technique allows for the creation of intricate designs that were previously unattainable with traditional methods, enabling jewelers to push the boundaries of creativity.

Furthermore, the rise of sustainable manufacturing practices is reshaping the jewelry sector. The 2021 Ethical Jewelry Report highlighted that 62% of consumers prefer brands that prioritize eco-friendly materials and processes. Electroforming not only allows for the use of recycled metals but also reduces waste by minimizing the amount of raw material needed for production. As brands increasingly align with consumer demand for sustainability, electroforming stands out as a viable solution that meets both aesthetic and ethical aspirations in jewelry design. The integration of these innovative trends is set to redefine jewelry manufacturing, making it more efficient, sustainable, and captivating for consumers.

The implementation of electroforming in jewelry design has rapidly gained traction due to its innovative approach and cost-effectiveness. According to a report by the Jewelers of America, the adoption of advanced technologies in jewelry manufacturing can reduce production costs by up to 30%. This statistic underlines the significance of electroforming, which allows intricate designs to be achieved with significantly less material wastage compared to traditional methods. By using a conductive substrate and electroplating, jewelers can produce detailed and lightweight pieces, pushing the boundaries of creativity.

To successfully implement electroforming, jewelers should prioritize a few best practices. First, selecting the right substrates is crucial; materials like wax or plastic can provide a solid foundation for the electroforming process. Additionally, maintaining clean working conditions ensures that contaminants do not compromise the final product's quality. Furthermore, understanding the electroforming parameters—such as current density and bath composition—can enhance the adhesion and durability of the resulting pieces.

Industry insights also suggest that jewelers who invest in employee training on electroforming techniques see a marked improvement in the precision and artistry of their designs, positioning themselves advantageously in the competitive market.

The future of electroforming jewelry manufacturing is poised for a significant transformation, particularly through advancements in sustainability and technology. With the electroforming equipment market projected to grow from $80,285 million to $131,546 million by 2030, achieving a compound annual growth rate of 6.37%, this sector is attracting considerable attention from both investors and manufacturers. The integration of eco-friendly materials and processes into the electroforming technique not only enhances production efficiency but also aligns with the growing consumer demand for sustainable practices in fashion.

Moreover, technological innovations are paving the way for more precise and intricate designs, elevating the artistry of jewelry making. Enhanced electroforming machines enable jewelers to create complex patterns and structures that were previously unattainable, expanding design possibilities while minimizing material waste. As these technologies continue to evolve, they will not only redefine jewelry aesthetics but also contribute to a more environmentally responsible manufacturing process. Through the marriage of sustainability and technology, the electroforming jewelry industry is set for a bright and promising future.