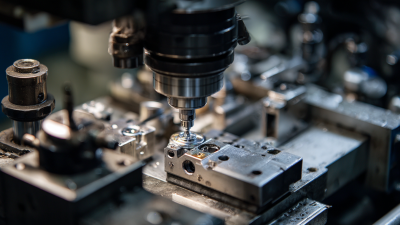

The jewelry industry is experiencing a transformative shift driven by technological advancements, particularly in the area of design and manufacturing. The integration of Cad Cam Jewelry Machines has revolutionized traditional methods, enabling jewelers to enhance precision and efficiency in their production processes. According to a recent market analysis by Research and Markets, the global market for CAD/CAM technology in the jewelry sector is projected to grow significantly, reaching an estimated $1.4 billion by 2025, driven by the increasing demand for customization and the reduction of product development timelines. As the industry embraces these innovations, understanding the future trajectory of Cad Cam Jewelry Machines becomes essential for jewelers aiming to stay competitive and cater to the evolving preferences of consumers. This blog will explore the nuances of these machines, their impact on design practices, and how they are shaping the future landscape of jewelry manufacturing.

The evolution of CAD CAM technology has significantly transformed the jewelry design landscape, enhancing creativity and efficiency like never before. According to a report by Grand View Research, the global market for CAD CAM jewelry equipment is expected to grow at a compound annual growth rate (CAGR) of over 7.4% from 2021 to 2028, reflecting the heightened demand for precision and customization in jewelry. This advancement allows designers to create intricate patterns and complex shapes that were previously impossible with traditional methods, enabling a level of artistry that resonates with modern consumer preferences.

Furthermore, the integration of CAD CAM technology streamlines the production process, reducing lead times and minimizing material waste. A study from Technavio suggests that adopting CAD CAM systems can decrease production costs by up to 30%, providing a compelling incentive for jewelry manufacturers to embrace this technology. As the industry continues to innovate, CAD CAM tools are becoming more user-friendly and accessible, empowering an even broader range of designers— from independent artisans to large-scale manufacturers—to leverage these capabilities in creating unique and personalized pieces that cater to a diverse clientele.

The advent of CAD CAM jewelry machines has revolutionized the jewelry industry, significantly benefiting artisans and designers. According to a recent report from Smithers, the global market for CAD CAM technology in the jewelry sector is expected to grow at a compound annual growth rate (CAGR) of 8.5% through 2025. This indicates a robust adoption of advanced technology among jewelry creators, emphasizing the tools' effectiveness in enhancing productivity and precision.

One of the key advantages of CAD CAM systems is their ability to streamline the design process. Artisans can transform their creative visions into digital models with ease, allowing for intricate designs that would be challenging to achieve manually. Additionally, a survey by the Jewelers of America revealed that 70% of jewelers who integrated CAD CAM reported reduced production times, enabling them to fulfill orders faster and cater to customer demands more efficiently. This technological integration not only uplifts craftsmanship but also boosts profitability, positioning artisans to thrive in an increasingly competitive market.

| Benefit | Description | Impact on Artisans |

|---|---|---|

| Increased Efficiency | CAD CAM machines significantly reduce the time required to create jewelry designs compared to traditional methods. | Allows artisans to produce more pieces in less time, increasing profitability. |

| Enhanced Precision | These machines provide high levels of accuracy in cutting and shaping materials, minimizing human error. | Results in better quality products, leading to higher customer satisfaction and repeat business. |

| Design Flexibility | CAD software allows for complex designs that would be difficult or impossible to achieve by hand. | Enables artisans to explore innovative designs and customize pieces for clients. |

| Cost Efficiency | Lower wastage of materials and reduced labor costs result in improved overall cost management. | Artisans can maintain competitive pricing while preserving profit margins. |

| Streamlined Workflow | Integration of CAD and CAM allows for a seamless transition from design to production. | Fosters creative workflow and helps artisans manage projects effectively. |

The integration of AI and automation in jewelry manufacturing is transforming the industry, heralding a new era of efficiency and creativity. As CAD/CAM technology evolves, the use of AI-driven design tools is enabling jewelry designers to push the boundaries of their imagination. These tools can analyze trends, suggest designs, and even predict customer preferences, allowing businesses to create bespoke pieces that meet consumer demand in real-time. Automation further complements this shift, streamlining production processes and reducing the time required to bring a design from concept to finished product.

Moreover, the implementation of robotics in manufacturing facilitates precision and consistency that manual labor cannot achieve. With automated machines capable of intricate tasks such as stone setting and polishing, jewelers can maintain high-quality standards while scaling up production. AI algorithms can also monitor and optimize the manufacturing workflow, minimizing waste and enhancing sustainability. As these technologies become more accessible, they not only empower established jewelers but also pave the way for emerging designers to enter the market, leveling the playing field in the competitive jewelry landscape.

When selecting the right CAD CAM system for your jewelry business, it’s essential to assess your specific needs and production goals. Start by evaluating the type of jewelry you create. Are you focused on intricate designs, or do you require a system that can handle mass production? Different systems offer varying capabilities in design complexity and production speed, making it crucial to match your software and hardware choices with your business model.

Additionally, consider the level of customer support and community resources available for each CAD CAM system. A robust support network can significantly ease the learning curve and troubleshooting process. Look for platforms with comprehensive tutorials, user forums, and responsive customer service. This will not only expedite your team’s training but also enhance overall productivity as you integrate new technologies into your workflow. By taking these factors into account, you can make a more informed decision that will propel your jewelry business into the future.

The advancement of 3D printing technology is revolutionizing the jewelry industry by introducing unprecedented levels of customization and efficiency in production. According to a report by SmarTech Analysis, the global 3D printing jewelry market is projected to reach $6.3 billion by 2025, highlighting a significant shift toward additive manufacturing methods. This transformation enables jewelers to create intricate designs that were once deemed impossible, fostering innovation that meets diverse consumer demands.

Furthermore, the integration of 3D printing with CAD/CAM jewelry machines allows for rapid prototyping and reduced lead times. A study from Wohlers Associates indicates that 46% of jewelry manufacturers are already utilizing 3D printing for producing final parts rather than just prototypes. This shift not only enhances design capabilities but also minimizes waste—an essential factor for sustainability in an industry often criticized for its environmental impact. As manufacturers continue to embrace this technology, the future of jewelry production looks set to embrace a fusion of traditional craftsmanship and modern innovation, ensuring that the sector remains competitive in a rapidly evolving marketplace.