In the rapidly evolving landscape of modern manufacturing, efficiency is not just a goal; it’s a necessity. The Box Chain Coupling Machine stands at the forefront of this revolution, offering unparalleled advantages that are reshaping production processes across various industries. As manufacturers face increasing pressure to enhance productivity while minimizing downtime, the innovative design and robust functionality of the Box Chain Coupling Machine provide a compelling solution. This technology not only streamlines operations but also integrates seamlessly with digital tools, fostering a smarter and more agile manufacturing environment. By harnessing the capabilities of the Box Chain Coupling Machine, businesses can unlock new levels of efficiency, positioning themselves for success in a competitive market.

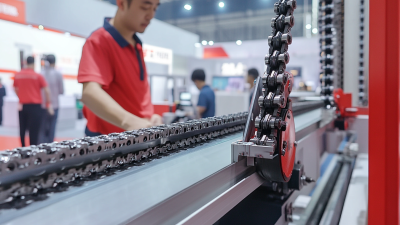

The modern manufacturing landscape demands efficiency and reliability, and box chain coupling machines have emerged as a pivotal solution to meet these needs. One of the primary advantages of these machines is their ability to transmit power effectively across various applications. With a robust design that minimizes slippage under heavy loads, box chain couplings ensure smooth operation even in the most demanding environments. This reliability translates into less downtime, allowing manufacturers to maintain high productivity levels.

Another significant benefit is the versatility offered by box chain coupling machines. These systems can be easily tailored to fit a variety of machinery setups, making them suitable for diverse production lines. Whether it’s for conveyor systems, printing presses, or any automated assembly, the adaptability of box chain couplings allows manufacturers to streamline their processes.

Furthermore, their relatively low maintenance requirements contribute to overall operational efficiency, reducing both labor costs and the need for frequent repairs. In a world where every second counts, the integration of box chain coupling machines in production systems can markedly enhance output and operational performance.

In the modern manufacturing landscape, the adoption of advanced technologies such as box chain coupling machines is proving to be essential for enhancing operational efficiency. Recent industry statistics indicate that in 2023, China alone experienced a remarkable growth in its gearbox market, reaching a valuation of 27.57 billion RMB with an output of approximately 25,900 units. This surge is primarily driven by the wind energy sector, highlighting the critical role gearboxes play in renewable energy applications.

One key advantage of box chain technology is its capability to streamline production processes, thereby reducing downtime and maintenance costs. For instance, the latest reports reveal that specialized cold chain logistics are imperative for ensuring temperature-sensitive goods are maintained within specified environments throughout the supply chain, a necessity in today's competitive marketplaces.

**Tip:** To maximize the benefits of box chain technology, manufacturers should invest in regular training for their workforce. Understanding the complexities of new machinery can lead to better utilization and fewer operational errors. Additionally, implementing predictive maintenance practices can further enhance machinery reliability and performance, ultimately contributing to superior product quality and increased customer satisfaction.

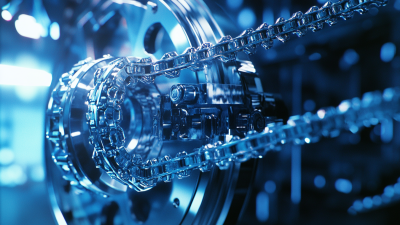

In the realm of modern manufacturing, the choice of coupling methods plays a pivotal role in operational efficiency. Box chain couplings stand out against traditional coupling methods due to their robust design and superior torque transmission capabilities. Unlike conventional couplings that may rely on rigid connections or flexible elements, box chain couplings utilize interlocking chains, which provide a more effective means of accommodating misalignment and deliver enhanced shock absorption. This feature is particularly advantageous in demanding applications, where minimizing downtime and maximizing productivity are crucial.

Moreover, the maintenance and longevity of box chain couplings further distinguish them from their traditional counterparts. Traditional couplings often require frequent adjustments and replacements, leading to increased maintenance costs and production interruptions. In contrast, box chain couplings tend to have a longer lifespan thanks to their durable construction and lower wear components. This reduced need for upkeep not only saves time but also allows manufacturers to allocate resources more efficiently, focusing on growth and innovation rather than extensive maintenance schedules. As manufacturers continue to seek solutions that improve productivity, the advantages of box chain couplings become increasingly apparent, setting a new standard in coupling technology.

In the rapidly evolving landscape of modern manufacturing, the integration of box chain coupling machines has emerged as a game-changer for efficiency. A recent report from KPMG highlights that manufacturers who have adopted advanced coupling technologies have seen a productivity increase of up to 30%. This significant boost is largely attributed to the reduction of downtime and the ability to manage high torque loads with ease. Real-world case studies are demonstrating how companies across industries are leveraging these machines to streamline their operations.

For instance, a leading automotive manufacturer implemented box chain coupling machines in their assembly line, resulting in a 40% decrease in maintenance costs over a year. According to a study by McKinsey, facilities utilizing these technologies reported an average reduction of equipment wear and tear by nearly 25%. By enhancing the reliability of machinery, manufacturers not only optimize their workflow but also improve overall safety standards in their operations, effectively supporting growth in an increasingly competitive market.

As the manufacturing sector continues to evolve, innovations in box chain coupling systems are paving the way for enhanced productivity and efficiency. These advancements not only streamline processes but also integrate seamlessly with existing machinery, allowing businesses to adapt quickly to changing demands. The introduction of smart technology into box chain couplings, such as sensors for real-time monitoring, can significantly reduce downtime and improve operational performance.

**Tip:** When considering the implementation of advanced box chain couplings, evaluate your current machinery compatibility to ensure a smooth integration and maximize the benefits of these innovations.

Moreover, the trend towards automation in manufacturing means that box chain couplings are becoming smarter, with predictive maintenance functionalities. This proactive approach helps in anticipating potential failures before they occur, thus saving costs and improving productivity in the long run.

**Tip:** Regularly train your team on the latest technologies and practices in box chain coupling to harness their full potential and drive operational efficiency.