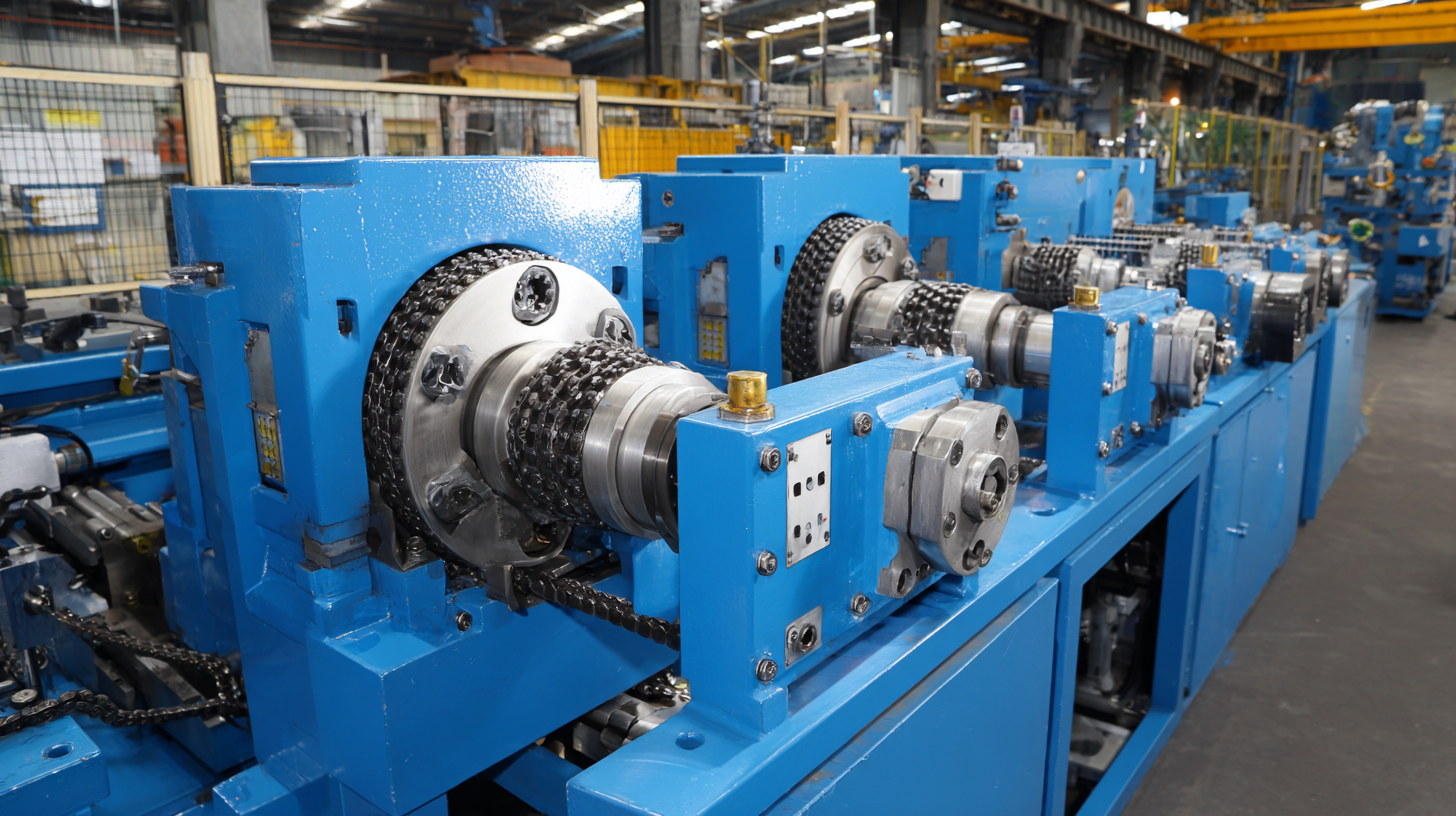

When it comes to enhancing productivity and efficiency in manufacturing, selecting the right equipment is paramount. The Automatic Chain Hammer Machine has emerged as a vital tool for various production processes, combining speed with precision. However, with an array of options available in the market, choosing the ideal model to suit your specific production needs can be overwhelming. This guide aims to provide you with seven essential tips to navigate the selection process effectively. By understanding the core functionalities, assessing your production requirements, and considering factors such as durability, maintenance, and compatibility, you can make a well-informed decision. Selecting the right Automatic Chain Hammer Machine not only streamlines your operations but also boosts overall output, making it a crucial investment for any manufacturing business.

When selecting an automatic chain hammer machine, several key factors significantly influence production efficiency. First, machine capacity and speed play a crucial role. According to a recent report by the International Manufacturing Institute, machines that operate at higher speeds can improve production rates by up to 30%, leading to lower operational costs over time. Thus, evaluating your production volume and required processing speed can streamline your selection process.

Additionally, the machine's adaptability to different materials is essential. A versatile automatic chain hammer machine can handle various materials without compromising quality, thus enhancing overall productivity. Industry studies suggest that machines with adjustable settings minimize material waste and reduce setup times, which are often cited as significant challenges in production environments.

Tip: Always consider the machine's energy efficiency. Machines that use advanced technology to reduce energy consumption can lead to substantial savings. Look for models that meet or exceed energy efficiency standards, as highlighted in recent Sustainability in Manufacturing reports, which indicate that energy-efficient machines can cut operating costs by approximately 20%. This not only benefits your bottom line but also contributes to a more sustainable production process.

| Feature | Importance | Considerations | Average Price Range |

|---|---|---|---|

| Production Capacity | High | Match with your daily production requirements | $5,000 - $15,000 |

| Durability | Medium | Material quality and construction | $4,000 - $12,000 |

| Ease of Use | High | Control system and operator interface | $3,000 - $10,000 |

| Maintenance Requirements | Medium | Frequency and parts availability | $2,000 - $8,000 |

| Safety Features | High | Emergency stops, guards, etc. | $5,000 - $10,000 |

| Customization Options | Medium | Adapt to specific production needs | $4,000 - $15,000 |

| Energy Efficiency | High | Lower operational costs | $3,000 - $7,000 |

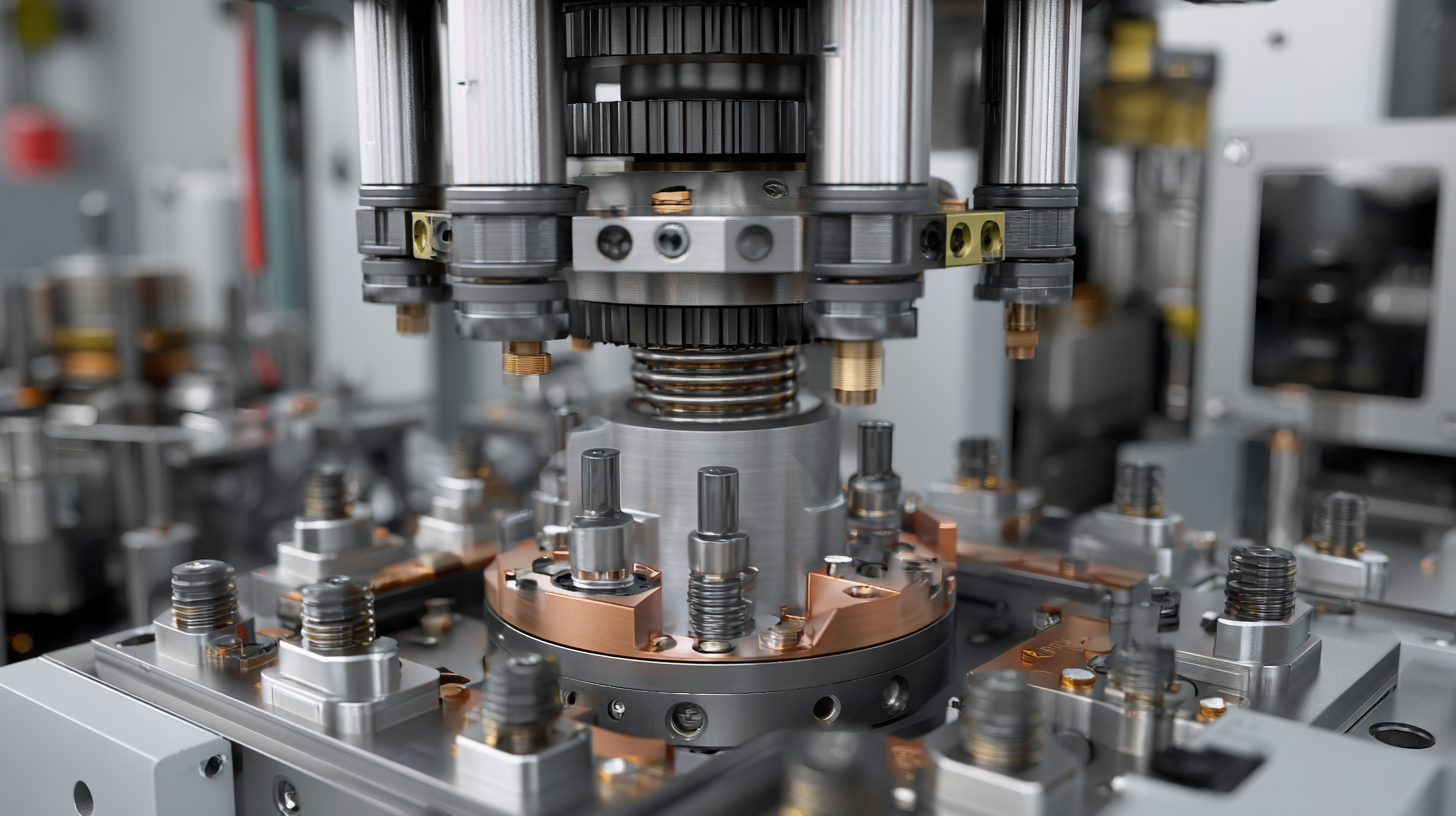

When selecting the right automatic chain hammer machine for your production needs, understanding the mechanical specifications is crucial. Key factors such as power, speed, and impact energy requirements significantly influence the machine's performance and suitability for your specific tasks. The power rating of the machine determines its capability to handle various materials and perform tasks effectively. A higher power rating typically means the machine can exert greater force, making it essential for heavy-duty applications.

Speed is another vital aspect to consider. The operational speed of the hammer can affect the overall production efficiency and throughput. Machines with adjustable speed settings provide flexibility, allowing users to optimize their production processes for different materials and applications. Additionally, the impact energy of the hammer plays a critical role in determining the machine’s effectiveness in forging or shaping materials. Sufficient impact energy ensures that the hammer can penetrate and compress materials adequately, yielding the desired results in your production line. Balancing these mechanical specifications is key to selecting the appropriate machine that meets your operational demands and enhances productivity.

When selecting an automatic chain hammer machine, understanding your production volume needs is crucial. The output rate directly influences the type of machine that will be most beneficial for your operations. If you're handling low to moderate production volumes, a machine with variable speed settings might suffice, allowing flexibility while managing different tasks. However, for higher output requirements, investing in a high-capacity machine that can operate continuously at a consistent rate will be essential to meet your production goals without delays.

One vital tip is to assess your future production needs alongside your current demands. A machine that meets your existing output capabilities may fall short as your business grows. Another important consideration is the speed and efficiency of the machine. A model with higher throughput can significantly enhance productivity, reducing cycle times and increasing overall efficiency. Always evaluate the machine's durability and maintenance needs to avoid unexpected downtimes that could impact production schedules.

When selecting an automatic chain hammer machine, assessing material compatibility is crucial to ensuring efficient production. Different chain types and sizes require specific handling capabilities, and the machine must be able to accommodate these variations. For instance, lighter chains may require less force and faster cycle times, while heavier chains will need more robust machinery to handle their weight without compromising performance. Understanding the specifications of the chains you intend to use will guide you in selecting a machine that precisely meets these demands.

Furthermore, it is essential to consider the material composition of the chains. Various metals and coatings can affect how the machine interacts with the chains during production. A machine that is designed to work with steel chains may not perform adequately with those made of aluminum or a composite material. Thus, verifying that the automatic chain hammer machine is compatible with the specific materials you plan to use will prevent costly errors and downtime. Engaging with manufacturers to obtain detailed information about their equipment’s compatibility can greatly enhance your production efficiency and product quality.

When selecting an automatic chain hammer machine, evaluating maintenance and support options is paramount for long-term operational success. Machines require routine upkeep to ensure optimal performance, thus understanding the frequency and complexity of maintenance tasks is crucial. Investigate the manufacturer’s maintenance schedule and whether they offer comprehensive service packages. A well-structured plan can help mitigate unexpected downtime and maintain production efficiency, ultimately affecting the overall cost of ownership.

Moreover, consider the availability of service and spare parts. A reputable manufacturer should provide not only initial training and installation support but also ongoing assistance as needed. Check the geographic coverage of their service network and the responsiveness to service requests. This can dramatically impact your production capabilities, ensuring that any issues are resolved quickly, limiting disruptions.

Long-term cost considerations become clearer when you assess these support avenues; investing in a reliable machine with accessible maintenance and support can save significant costs in the event of breakdowns, enhancing productivity and safeguarding your investment.

Choosing the right Automatic Chain Hammer Machine is critical for maximizing production efficiency. Key factors to consider include the mechanical specifications such as power, speed, and impact energy requirements, which determine the machine's performance capabilities. Additionally, analyzing production volume needs will help in selecting a machine that meets the desired output rate. It’s also essential to assess material compatibility to ensure that the machine can handle specific chain types and sizes effectively.

Long-term cost considerations play a significant role; evaluating maintenance and support options will help in budgeting for future expenses. Lastly, exploring technological features such as automation and smart controls can significantly enhance productivity, making the Automatic Chain Hammer Machine not only a tool but also a strategic asset in your production process. These considerations together guide businesses in making informed choices tailored to their unique production needs.