In the ever-evolving landscape of manufacturing, the choice of equipment can significantly impact product quality and operational efficiency. Among these, the Gold Buffing Machine has emerged as a crucial tool for achieving a flawless finish on gold and other precious metals. According to a recent market analysis by Grand View Research, the global metal finishing market is projected to reach $27.5 billion by 2025, underscoring the increasing demand for high-quality finishing processes. In particular, the rising trend of customization and the need for intricate detailing in jewelry manufacturing drive the necessity for advanced buffing solutions. Thus, understanding how to select the best Gold Buffing Machine tailored to unique manufacturing needs becomes indispensable for businesses striving to uphold quality standards while competing on a global scale. "精工细造,中国制造,服务世界" encapsulates this pursuit of excellence, guiding manufacturers towards achieving superior craftsmanship that resonates worldwide.

In the jewelry manufacturing industry, gold buffing machines play a crucial role in achieving a polished and professional finish on products. The importance of these machines extends beyond mere aesthetics; they enhance the quality of the final product, ensuring that pieces not only catch the eye but also meet industry standards. According to industry reports, well-finished gold jewelry can command up to 30% higher prices in the market. This underscores the value of investing in high-quality buffing machinery to elevate manufacturing outcomes.

When choosing the best gold buffing machine, it is essential to consider various factors, including the machine's speed, versatility, and compatibility with different gold grades. Tip: Invest in a machine that offers adjustable speed settings to efficiently handle various tasks without compromising on quality. Additionally, make sure to select a machine that allows for easy maintenance and replacement of buffing wheels for optimal performance.

Another important aspect is the machine's energy consumption. As manufacturers aim to improve sustainability, selecting energy-efficient models can significantly lower operational costs. Tip: Research and compare the energy ratings of different machines to find one that aligns with your sustainability goals while providing the necessary power for effective buffing. Emphasizing the right choice in gold buffing machines can lead to improved product quality and increased profitability for jewelry businesses.

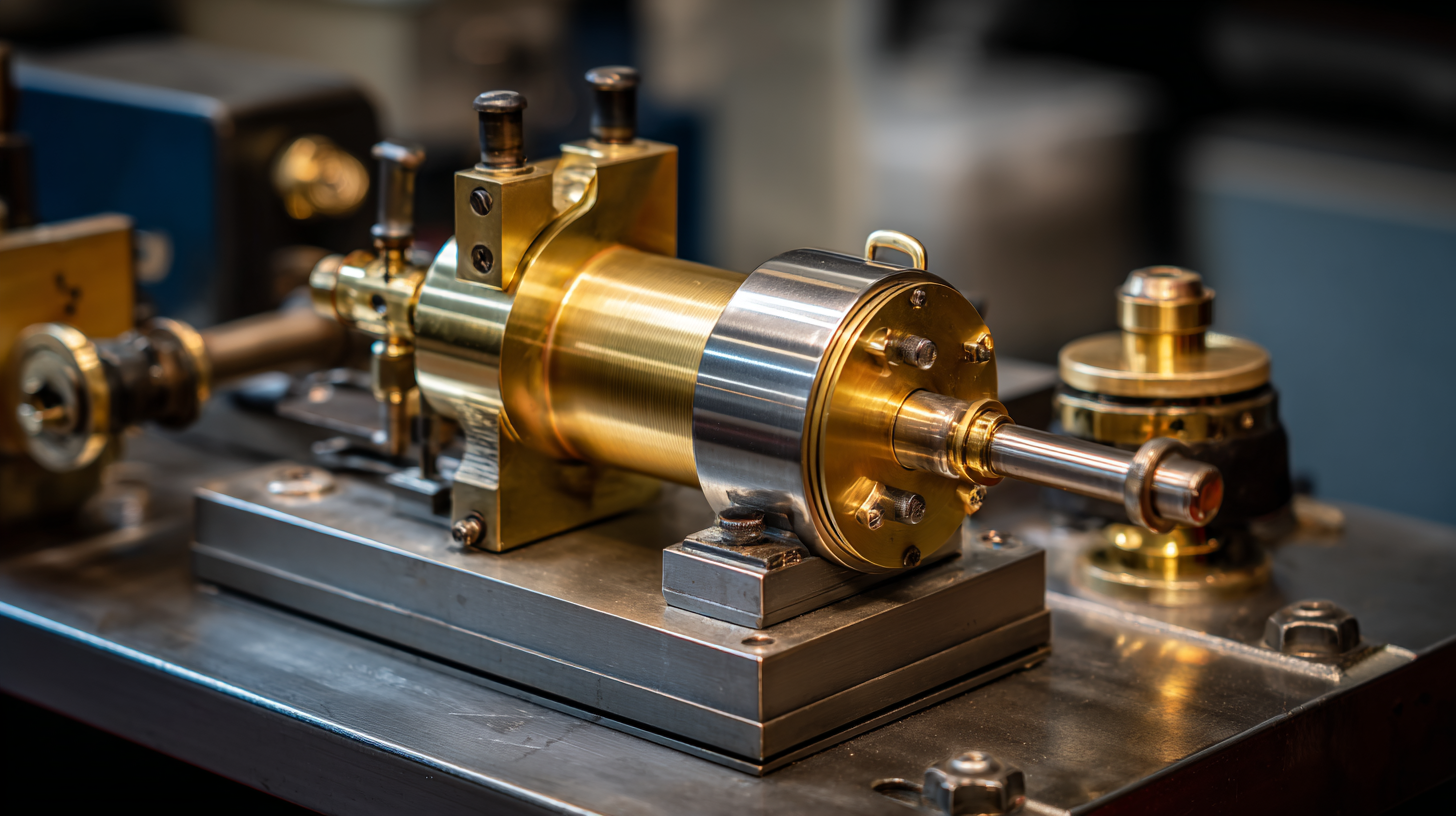

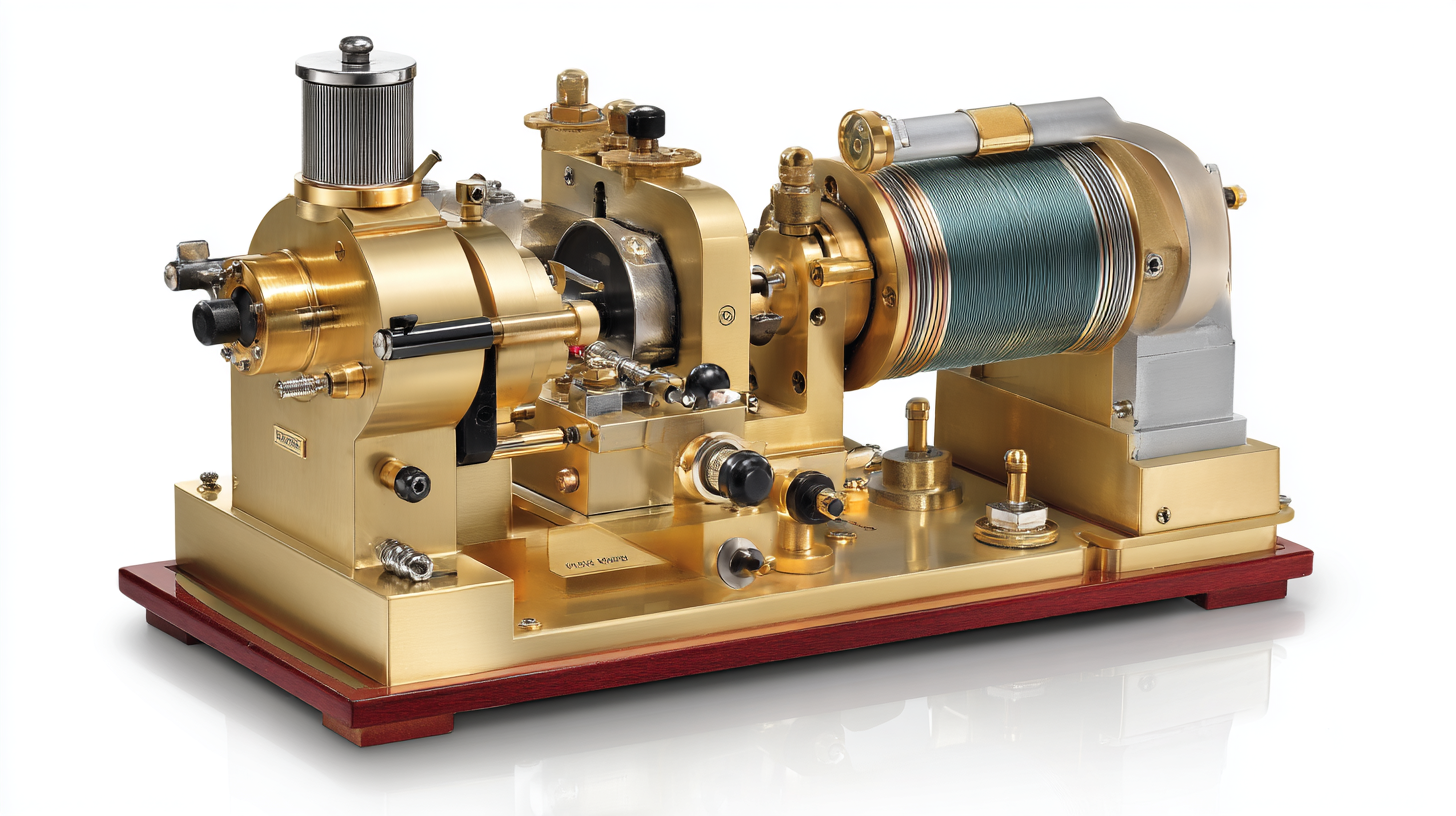

When selecting the best gold buffing machine for your manufacturing needs, it's essential to focus on key features that will enhance both efficiency and quality. One of the most critical aspects to consider is the machine's motor power and speed. A powerful motor ensures that the machine can handle various gold alloys seamlessly, while adjustable speed settings allow you to customize the buffing process for different types of items, from intricate jewelry to larger pieces.

Another important feature is the type of buffing wheels and pads included with the machine. Look for machines that offer a variety of materials, such as cotton, felt, or foam, since each offers distinct benefits for finishing. A machine that supports quick-change buffing pads can significantly reduce downtime, allowing for faster production times. Additionally, consider the ergonomics and ease of use, as a user-friendly design will enhance operator comfort and efficiency, making it easier to achieve that perfect shine on your gold products.

| Feature | Description | Importance Level |

|---|---|---|

| Motor Power | Higher motor power provides better performance and efficiency. | High |

| Buffing Speed | Speed adjustments allow for handling different materials and finishes. | Medium |

| Design | Ergonomic design facilitates easier operation and reduces fatigue. | Medium |

| Dust Collection | Effective dust collection maintains a clean working environment. | High |

| Weight | Lightweight machines are easier to move and operate in different setups. | Low |

| Safety Features | Built-in safety features protect the operator during use. | High |

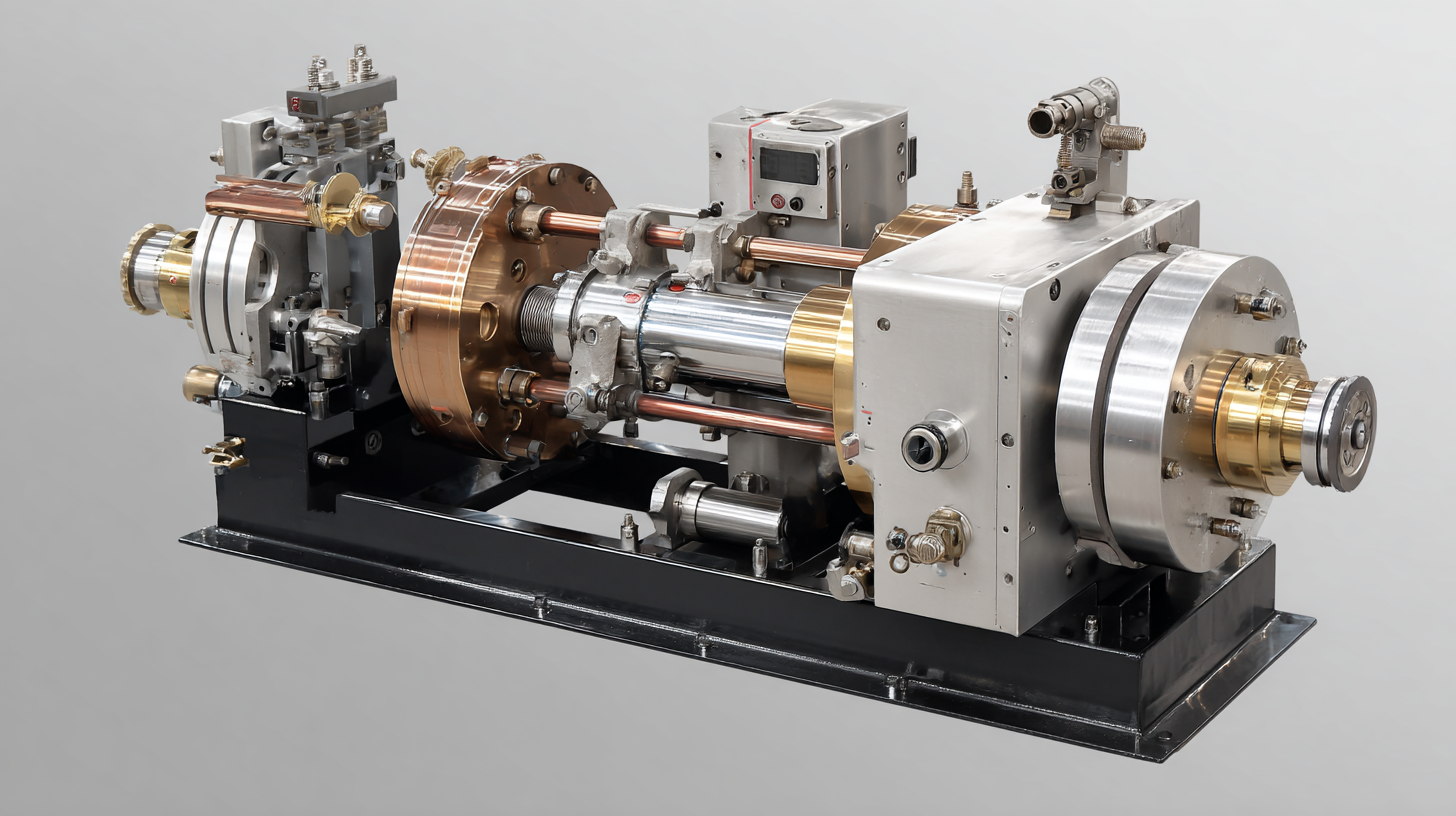

When selecting the best gold buffing machine for your manufacturing needs, it's essential to evaluate the different types available on the market. The primary categories include rotary buffing machines, belt-driven systems, and oscillating models. Each type offers distinct advantages that should align with your specific production requirements.

Rotary buffing machines are known for their efficiency and speed, making them suitable for high-volume operations. In contrast, belt-driven systems provide versatility and are often favored for delicate tasks requiring precision.

Additionally, considering the materials and applications is crucial in making the right choice. For instance, if you are working with rare earth elements like neodymium, praseodymium, or samarium, the buffing machine must accommodate the specific properties of these materials.

By assessing factors such as the abrasive quality, the machine’s ability to manage heat, and its overall durability, manufacturers can ensure optimal performance and longevity. Ultimately, understanding your specific production requirements and aligning them with the features of different buffing machines is the key to making an informed decision.

When it comes to maintaining optimal gold buffing performance, regular upkeep of your buffing machine is crucial. According to industry reports, a well-maintained buffing machine can enhance polishing efficiency by up to 30%, significantly improving the appearance of jewelry pieces. This efficiency is vital in a competitive manufacturing environment, where the quality of finish can set a product apart in the market.

To ensure your gold buffing machine performs at its best, implement a routine maintenance schedule. This includes checking and replacing worn buffing wheels, cleaning the machine to prevent metal dust buildup, and ensuring that all moving parts are well-lubricated. Neglecting these steps can lead to a decrease in performance, prolonging production times and potentially diminishing the quality of the finish. Additionally, incorporating cleaning solutions designed specifically for gold can further elevate your polishing results, much like the impact seen with top-performing jewelry cleaners in recent tests.

These practices not only extend the lifespan of your machinery but also enhance the brilliance of the jewelry you produce.

When considering the best gold buffing machine for your workshop, having a clear checklist can streamline the selection process. Start by identifying your manufacturing needs, such as the volume of production and the specific types of items you'll be polishing. A machine that caters to your particular requirements will enhance efficiency and output quality. Additionally, assess the machine's speed and versatility; the ability to adjust settings for different materials and finishes can significantly increase its utility.

Another crucial factor is the machine's durability and maintenance requirements. Look for robust construction and good warranties, as these aspects indicate a machine that can withstand continuous use. As seen in communities like the Calgary Rock and Lapidary Club, where hobbyists turn stones into stunning jewelry, investing in a reliable buffing machine can elevate the quality of your creations. Finally, consider user feedback and professional recommendations to ensure that the machine you choose not only meets your needs but also contributes positively to your craftsmanship.