In today's competitive market, choosing the best Automatic Jewelry Making Machine is crucial for businesses looking to streamline production and enhance creativity. With the rapid advancements in technology, an array of machines is available, each offering unique features that can significantly impact your jewelry-making process. This guide aims to provide valuable insights on how to navigate through the numerous options, ensuring you select a machine that aligns with your specific business needs. Whether you are a fledgling artisan or an established manufacturer, understanding the essential factors such as production capacity, versatility, ease of use, and cost-effectiveness will empower you to make an informed decision. Join us as we explore the key considerations that will help elevate your jewelry-making endeavors to new heights.

When selecting the best automatic jewelry making machine for your business, it is crucial to understand your specific jewelry production needs. The jewelry industry accounted for a staggering 43.68% share of global gold demand in 2024, utilizing about 2012 metric tons of gold. This substantial demand underscores the importance of efficiency and scalability in your production process. A machine tailored to your production volume can significantly enhance your output and maintain quality, which is vital in such a competitive market.

**Tip:** Assess the complexity of your designs before choosing a machine. If your creations require intricate detailing, opt for machines that offer precision and versatility, allowing you to explore a wider range of designs without sacrificing quality.

Moreover, considering costs and production capacity is essential. With rising gold prices impacting many established brands, focusing on cost-effective production methods without compromising quality can set your business apart. Reports indicate that operational halts are occurring in response to these prices, making it vital for new businesses to remain agile and responsive to market conditions.

**Tip:** Consider integrating eco-friendly practices into your production to appeal to the growing environmentally-conscious consumer base. Implementing sustainable practices not only contributes positively to the industry but can also enhance your brand's reputation and attract a wider audience.

| Feature | Importance Level | Recommended Option | Price Range |

|---|---|---|---|

| Production Speed | High | High-Speed CNC Router | $5,000 - $10,000 |

| Material Versatility | Medium | Multi-Material Laser Cutter | $3,000 - $7,000 |

| Ease of Use | High | User-Friendly 3D Printer | $2,000 - $4,000 |

| Maintenance Requirements | Medium | Low-Maintenance Machine | $2,500 - $5,500 |

| Precision and Accuracy | High | Precision Casting Machine | $6,000 - $12,000 |

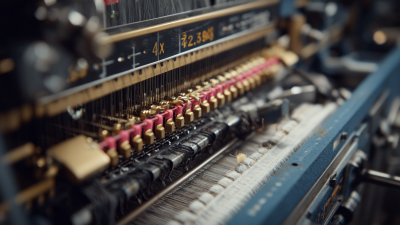

When selecting the best automatic jewelry making machine for your business, it's crucial to consider several key features that can significantly impact your production efficiency and product quality. One primary feature is the machine's versatility. Many modern automatic machines can handle a variety of materials, from gold to silver and even synthetic stones, allowing jewelers to diversify their offerings. According to a report by Grand View Research, the global jewelry market is expected to reach USD 480.5 billion by 2025, highlighting the necessity for machines that can adapt to evolving trends.

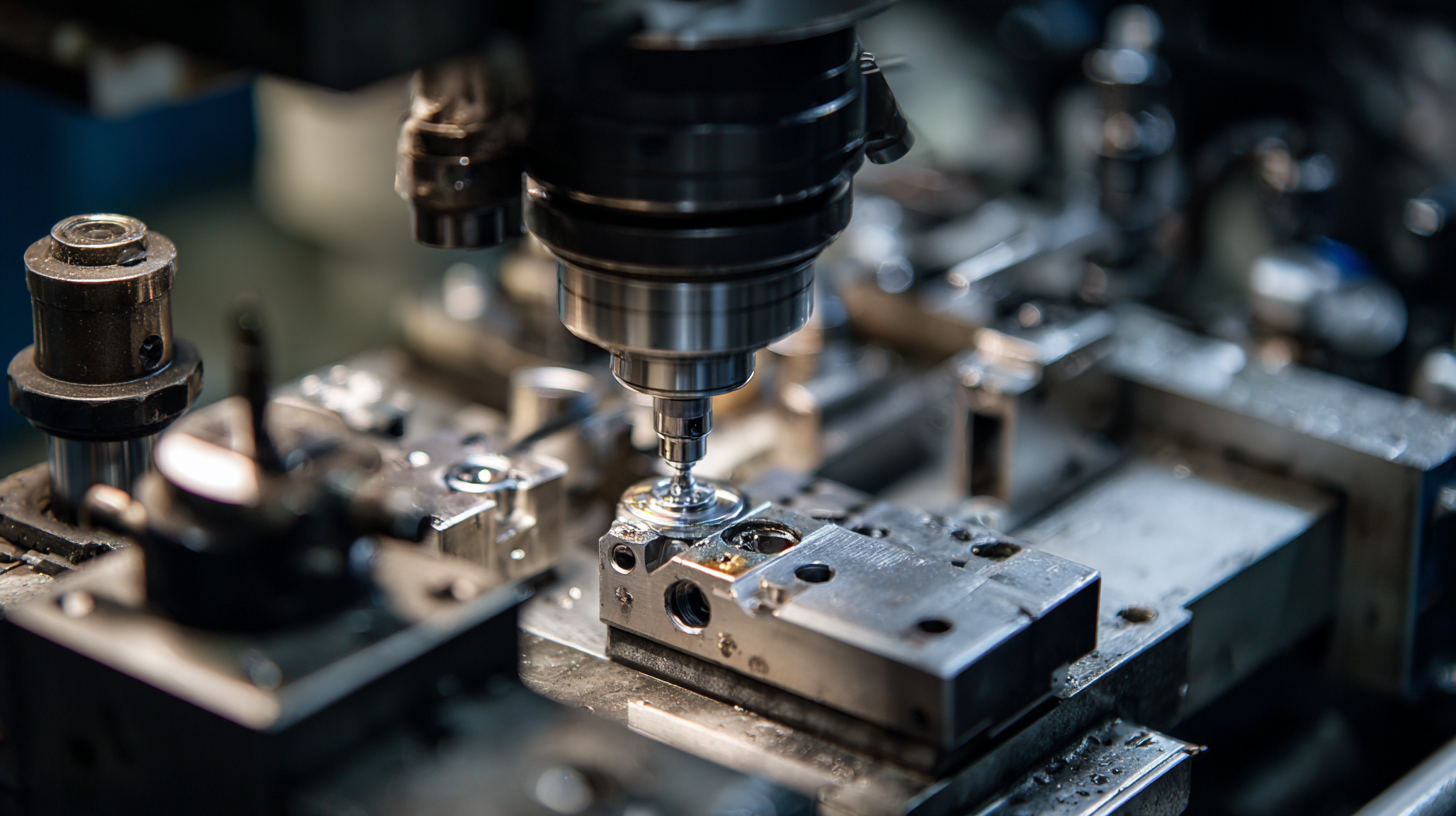

Another vital aspect is the precision and speed of the machine. Features such as computer numerical control (CNC) technology ensure that each piece is crafted with high accuracy. Data from IBISWorld indicates that businesses utilizing advanced manufacturing processes, such as CNC machining, have a 20% higher efficiency rate compared to those relying on manual methods.

**Tips:** Always check the machine's compatibility with your designed products. Look for features such as programmable settings which allow for quicker changeovers between designs and ensure minimal downtime. Investing in machines with robust after-sales support can also be a game-changer, providing you with necessary maintenance and training resources. Additionally, consider machines with energy-efficient operations to help reduce overall production costs.

When it comes to selecting an automatic jewelry making machine for your business, budgeting plays a critical role. Understanding the costs associated with different machines can help you find one that fits your financial plan without compromising on quality. Start by assessing your business needs—are you a startup aiming for smaller-scale production, or do you need a more robust model for higher volume? This understanding will guide you in determining how much you can afford and which features are essential.

It’s vital to consider not just the upfront costs but also ongoing expenses, such as maintenance and potential upgrades. Many businesses today are feeling the financial strain, necessitating careful planning to stretch every dollar further. Opting for budget-friendly equipment can be an effective way to balance quality and cost; look for machines that have similar features to higher-end models but at a fraction of the price. By investing wisely, you can leverage your equipment to enhance productivity while staying within budget, ultimately positioning your business for better growth opportunities.

When it comes to selecting an automatic jewelry making machine, comparing different brands and models is crucial to ensure quality assurance. Each manufacturer typically offers a distinct set of features, capabilities, and build quality, which can significantly impact the efficiency and output of your jewelry business. Brands like Roto-Die and Gesswein are renowned for their precision and durability, making them ideal for high-volume production environments. Evaluating the materials used, customer reviews, and warranty offerings can provide insight into which machine will best meet your operational needs.

Additionally, it’s important to consider the specific functionalities of various models. Some machines might excel in intricate detail work, while others are designed for rapid mass production. Features such as programmable settings, ease of use, and maintenance requirements play a vital role in the machine's longevity and your productivity. Conducting thorough research and possibly seeking out demonstrations will help you make an informed decision that aligns with your business goals and ensures that you invest in a machine that delivers the quality and consistency your jewelry designs demand.

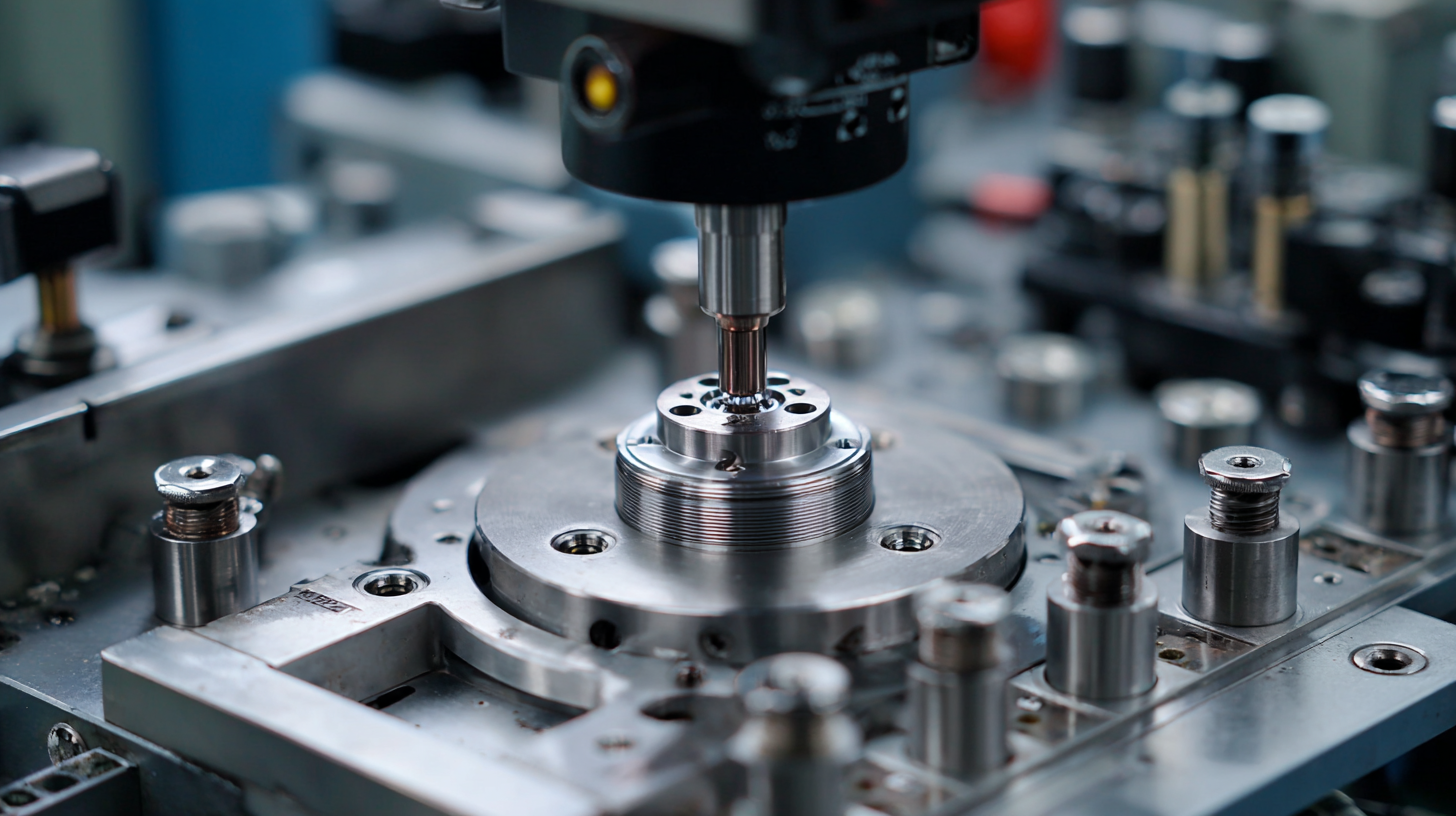

When investing in an automatic jewelry making machine, maintenance and support play a crucial role in ensuring the longevity of your equipment. Regular maintenance routines, which include cleaning, lubricating moving parts, and inspecting for wear and tear, can prevent major issues that may arise from neglect. Establishing a schedule for these tasks helps in prolonging the lifespan of the machine, ultimately protecting your investment. Furthermore, understanding the specific maintenance requirements as outlined in the manufacturer’s manual is essential for optimal performance.

When investing in an automatic jewelry making machine, maintenance and support play a crucial role in ensuring the longevity of your equipment. Regular maintenance routines, which include cleaning, lubricating moving parts, and inspecting for wear and tear, can prevent major issues that may arise from neglect. Establishing a schedule for these tasks helps in prolonging the lifespan of the machine, ultimately protecting your investment. Furthermore, understanding the specific maintenance requirements as outlined in the manufacturer’s manual is essential for optimal performance.

In addition to routine maintenance, having reliable support from the manufacturer or supplier can make all the difference. It is important to choose a machine from a brand known for exceptional customer service and support. This includes access to technical assistance, readily available spare parts, and training resources for your staff. A responsive support system ensures that any issues can be addressed quickly, minimizing downtime and maintaining productivity. By prioritizing both maintenance practices and support options, jewelry businesses can maximize the efficiency and durability of their automatic machines, allowing them to thrive in a competitive market.