In today's fast-paced manufacturing landscape, the demand for efficiency and reliability in machinery has never been higher. The Bismark Chain Coupling Machine stands out as a pivotal innovation, tailored to enhance operational performance across various industries. According to a recent industry report by Grand View Research, the global coupling market is projected to reach USD 6.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.2%. This underscores the significance of advanced coupling solutions like the Bismark Chain Coupling Machine, which offers exceptional torque transmission and minimizes downtime. By integrating advanced engineering technologies, these machines not only improve performance but also reduce maintenance costs, making them an invaluable asset in any production line. As we delve deeper into the unique advantages of Bismark Chain Coupling Machines, we will discover how they can transform operational efficiencies and drive competitive advantage in today's market.

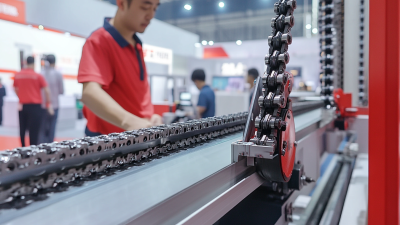

Bismark Chain Coupling Machines stand out for their unique functionality, serving as an indispensable component in various industrial applications. These machines effectively transmit power between rotating shafts while accommodating misalignments and fluctuations in load. Utilizing a robust chain mechanism, Bismark Chain Couplings enhance reliability and ensure consistent performance, making them ideal for heavy-duty operations. Their design minimizes wear and tear, significantly extending the lifespan of machinery while reducing the need for frequent maintenance.

What sets Bismark Chain Coupling Machines apart is their ability to absorb shock loads and vibrations, which can be detrimental to traditional coupling systems. This characteristic not only protects the equipment connected to the couplings but also contributes to smoother operational efficiency and reduced downtime. Furthermore, their adaptability allows for easy integration into existing systems, providing manufacturers with a cost-effective solution to optimize mechanical performance. In essence, understanding the intricate functionality of Bismark Chain Coupling Machines reveals their vital role in advancing industrial operations and enhancing overall productivity.

Bismark Chain Coupling Machines stand out in the realm of industrial equipment, offering distinct advantages that enhance overall performance. One of the key features is their robust construction, designed to withstand demanding operational environments. Crafted from high-quality materials, these machines minimize wear and tear, ensuring longevity and reliability. This durability is crucial for maintaining efficiency in production lines, reducing downtime for maintenance and repairs.

Another significant advantage lies in the advanced design of Bismark Chain Coupling Machines, which ensures smooth and efficient power transmission. The precision engineering allows for minimal energy loss during operation, contributing to improved performance and lowered operational costs. Additionally, the unique coupling mechanism provides enhanced flexibility and adaptability, accommodating various applications without compromise. With these key features, Bismark Chain Coupling Machines not only boost productivity but also lead the charge in sustainability on the shop floor, making them an investment worth considering for any forward-thinking business.

When evaluating coupling solutions for industrial applications, Bismark Chain Coupling Machines stand out when compared to traditional couplings. Traditional couplings, while effective, often face limitations in terms of flexibility and durability. They typically rely on a rigid design that can lead to premature wear and alignment issues, especially in high torque environments. In contrast, Bismark Chain Coupling Machines utilize a chain mechanism that allows for greater misalignment and movement without compromising performance. This unique design enables them to absorb shocks and vibrations more effectively, which ultimately leads to a longer lifespan and reduced maintenance costs.

Furthermore, the adaptability of Bismark Chain Coupling Machines makes them a superior choice in various applications. Unlike traditional couplings, which can require frequent adjustments and replacements, Bismark's design is engineered to handle diverse operational demands without losing efficiency. The ability to accommodate different loads and environments makes these coupling machines ideal for industries ranging from manufacturing to transportation. As a result, organizations can achieve enhanced performance while minimizing downtime, showcasing the progressive benefits of choosing Bismark over conventional coupling systems.

Bismark Chain Coupling Machines have emerged as a vital component across multiple industries, showcasing their versatility and efficiency. In the manufacturing sector, for instance, these machines facilitate the seamless transfer of power and movement, ensuring optimal performance in assembly lines. According to a recent industry report by MarketsandMarkets, the demand for coupling machines is projected to grow at a CAGR of 4.5% from 2023 to 2028, driven by the increasing automation in manufacturing processes.

In the agricultural sector, Bismark Chain Coupling Machines play a crucial role in enhancing machinery performance, particularly in the operation of tractors and harvesters. By providing reliable torque transmission, these machines help reduce downtime and maintenance costs. A study by ResearchAndMarkets indicates that the adoption of advanced coupling technologies in agriculture can lead to a 15% increase in operational efficiency, showcasing their significant benefits.

**Tip**: When selecting a Bismark Chain Coupling Machine for your application, consider the specific torque requirements and operational conditions to ensure optimal performance and longevity. **Tip**: Regular maintenance checks are essential to maximize the efficiency of coupling machines, preventing costly downtime and enhancing overall productivity in your operations.

Bismark Chain Coupling Machines are renowned for their robust performance in various industrial applications. To ensure these machines operate at their best, regular maintenance is crucial. One of the key aspects is lubrication; keeping all moving parts well-lubricated minimizes friction and prevents wear. It’s advisable to use high-quality lubricants that match the specific requirements of the coupling machinery to avoid any potential breakdowns.

Additionally, regular inspections can help identify issues before they escalate. Check for any signs of misalignment or loosening components, as these can lead to inefficiencies and reduce the lifespan of the machine. Cleaning the coupling assembly from dust and debris is another vital maintenance tip. This not only boosts operational efficiency but also prevents potential hazards associated with overheating or mechanical failure. By following these maintenance guidelines, operators can significantly enhance the reliability and performance of Bismark Chain Coupling Machines, ensuring smooth and effective operations.

| Feature | Advantage | Maintenance Tip |

|---|---|---|

| High Torque Capacity | Enables efficient power transfer | Regularly inspect and tighten coupling bolts |

| Low Maintenance Requirements | Reduces operational downtime | Lubricate joints according to specification |

| Noise Reduction | Improves work environment | Monitor for unusual sounds and vibrations |

| Compact Design | Saves space in machinery layout | Keep the coupling area clean and free of debris |

| Versatility | Adapts to various operational conditions | Assess compatibility with different machinery |