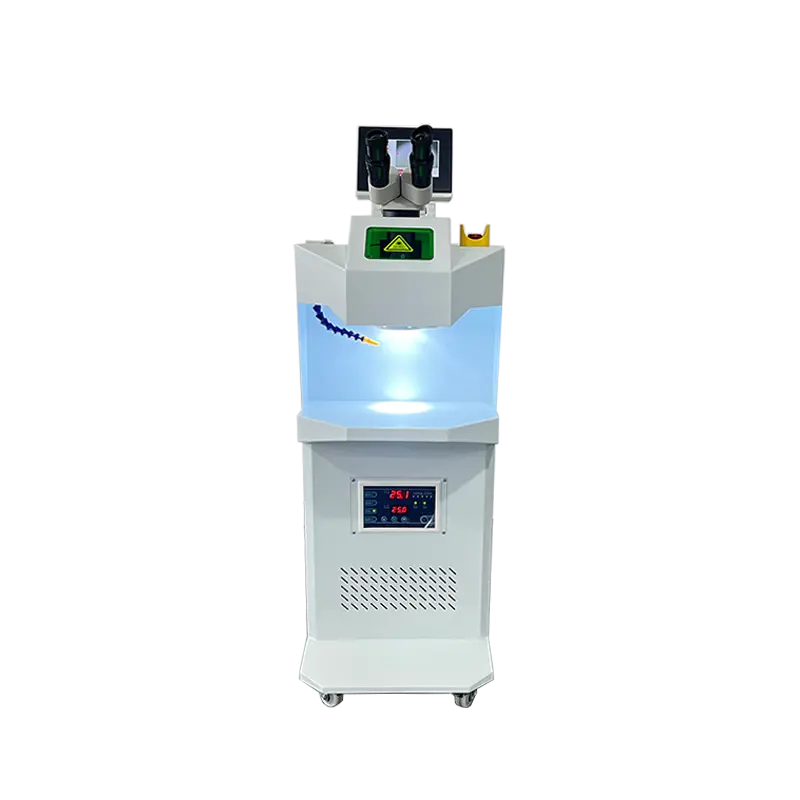

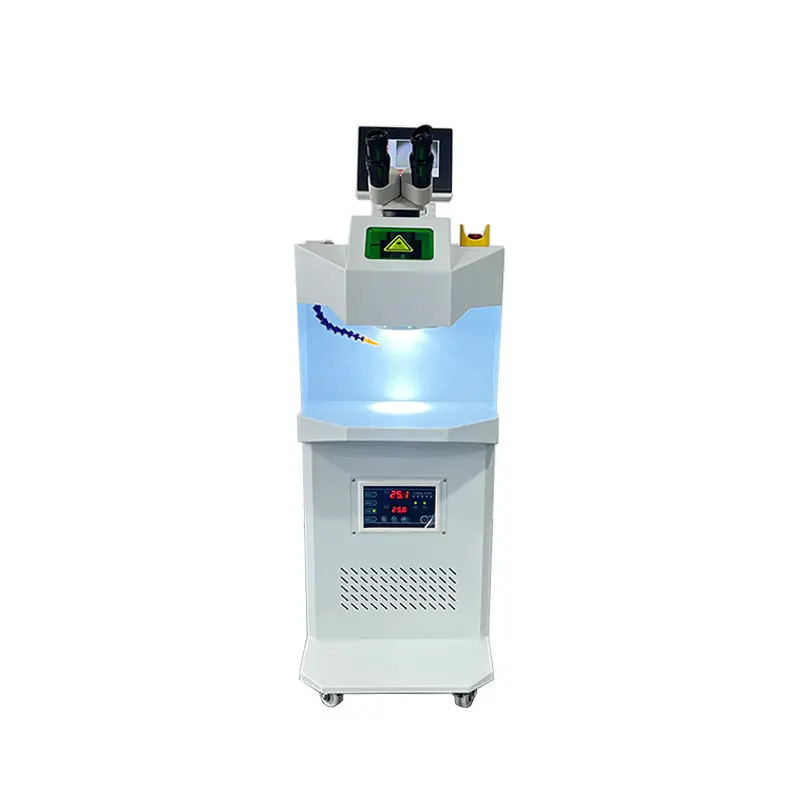

All-in-one jewelry laser welding machine

Vidoes

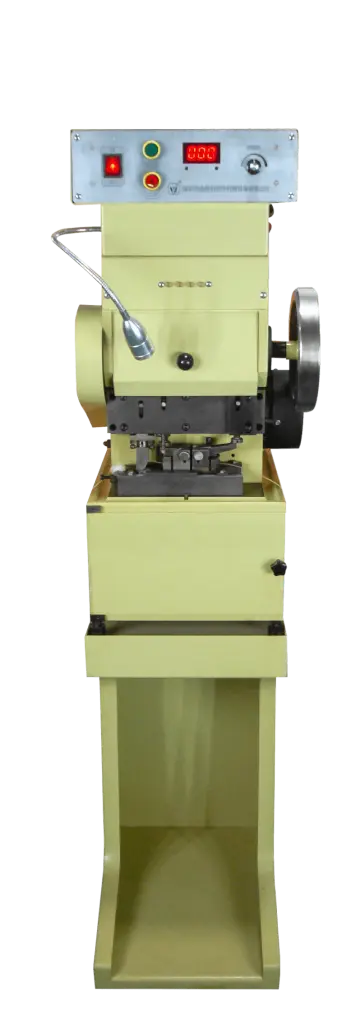

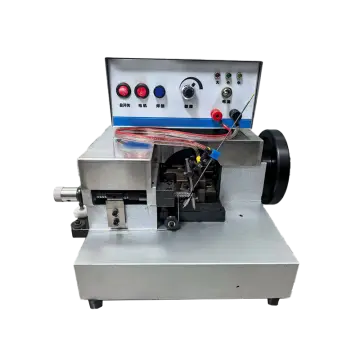

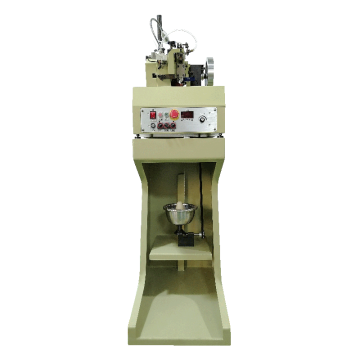

Product images:

Product Parameters

|

Machine model |

IMG-JW200A |

|

Max laser power |

200W |

|

Laser type |

YAG |

|

Laser wavelength |

1064nm |

|

Capacity control |

1-100% |

|

Pulse width regulation |

0.1-10MS |

|

Laser welding frequency |

1-15HZ |

|

Maximum single-pulse energy |

100J |

|

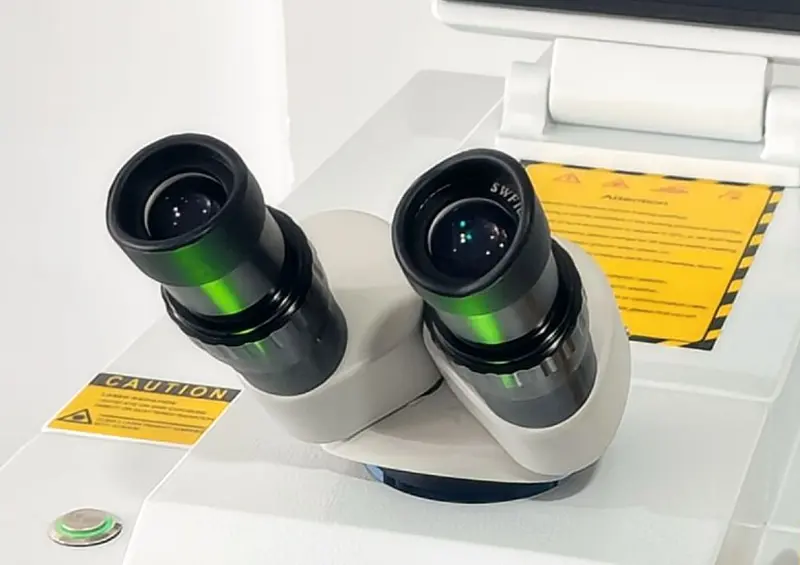

MIcroscope |

10X |

|

Instability of energy |

<2% |

|

Beam Divergence |

≤8mrad |

|

Welding the width |

0.4-3mm |

|

Welding the focal length |

F=110mm |

|

Continue working time |

16hours |

|

Noise |

≤60db |

|

Working temperature |

55°F(13°C)-95°F(35°C) |

|

Working Humidity |

5%-75% |

|

Oil mist |

≤15mg/m³ |

|

CCD |

720P CCD 7inches (with cross) |

|

Power required |

AC220V±10% 50HZ/60HZ |

|

Interiorinput power |

6KW |

|

Languages |

Chinese, English, Korean(Can be customized) |

|

Net size and weight |

800*400*1100mm 75KG |

|

Package size and weight |

860*460*1300mm 94KG |

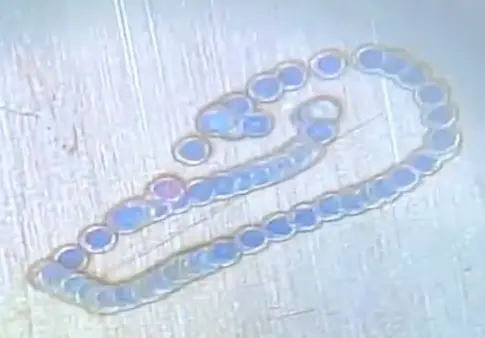

Welding effect

Product Features

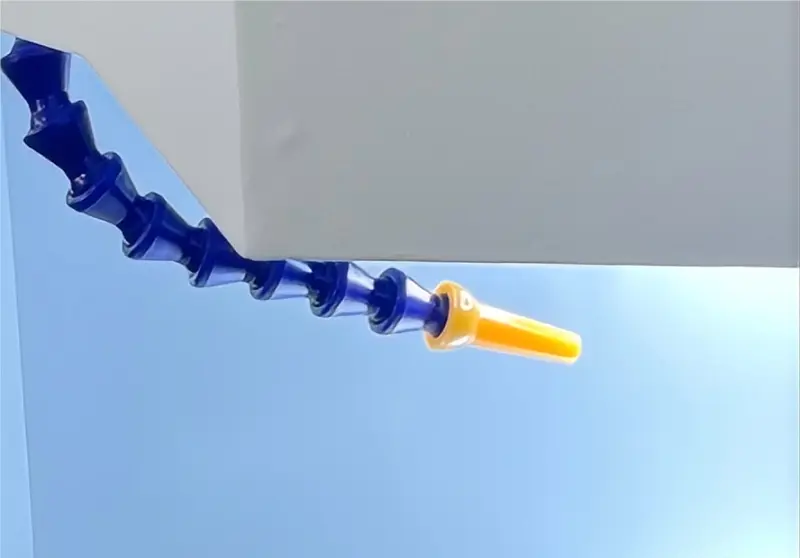

1. Energy, pulse width, frequency, and spot size can be adjusted within a large range to achieve various welding effects. The parameters are adjusted by a closed cavity control rod, which is simple and efficient.

2. Advanced ceramic spotlight chamber is adopted, which is corrosion-resistant, high-temperature resistant, and has high photoelectric conversion efficiency. The spotlight chamber and xenon lamp have a long service life.

3. Adopting advanced automatic shading system eliminates eye irritation during working hours.

4. It has the ability to work continuously for 16 hours, and the overall performance of the machine is stable.

5. Humanized design, conforms to ergonomics, and works for long hours without fatigue.

2. Advanced ceramic spotlight chamber is adopted, which is corrosion-resistant, high-temperature resistant, and has high photoelectric conversion efficiency. The spotlight chamber and xenon lamp have a long service life.

3. Adopting advanced automatic shading system eliminates eye irritation during working hours.

4. It has the ability to work continuously for 16 hours, and the overall performance of the machine is stable.

5. Humanized design, conforms to ergonomics, and works for long hours without fatigue.

Product Features

description2

Lily

Lily Jason wong

Jason wong